- Getting the right information to hand before the meeting

When scheduling a design meeting, it is important to ensure you have all the necessary project information at hand. The waterproofing specialist will be keen to understand the following, and if possible, this basic information can be distributed in advance.

- Project Name

- Location

- Is it a High-Risk Building, and is it bound by Gateway 1, 2, 3 of the Building Safety Act

- Expected start date on site (Piling and Groundworks contracts)

- Client name

- Structural engineer

- Architect

- Warranty provider (if appointed)

- Main contractor (if appointed)

- Groundworks contractor (if appointed)

- Build type (New Build, refurb etc)

- The Stage of the project (Current Riba Stage, and is it on site yet?)

This foundational information provides important details to help inform the discussion and direction of the meeting.

- Ensure key stakeholders attend

The success of a design meeting hinges on the presence of key stakeholders. So, who should attend? Ideally, the architect, structural engineer, and at least one design manager from the main contractor should attend.

While having all three is optimal, any combination of these individuals can still contribute positively to the discussion. At this stage, you may choose to include a groundworker who has been engaged at PCSA stage or a specialist installer.

By excluding essential stakeholders, you risk overlooking critical insights and perspectives.

- Have Essential Drawings and Documents to hand

A design meeting without the necessary drawings and documents is akin to sailing without a compass. To facilitate productive discussions, make sure you have the following to hand for ease of presentation:

- General arrangement (GA) plan for ground level and any below-ground levels

- Foundation plan (if drafted or completed)

- Sections through the basement, including edge detailing and lift pits

- Site investigation report or ground investigation survey

These documents and drawings provide the essential context needed for informed decision-making as the waterproofing strategy and other substructure protection design strategy comes together.

“Getting the right information is a vital first step “

- Research Key waterproofing and substructure protection considerations

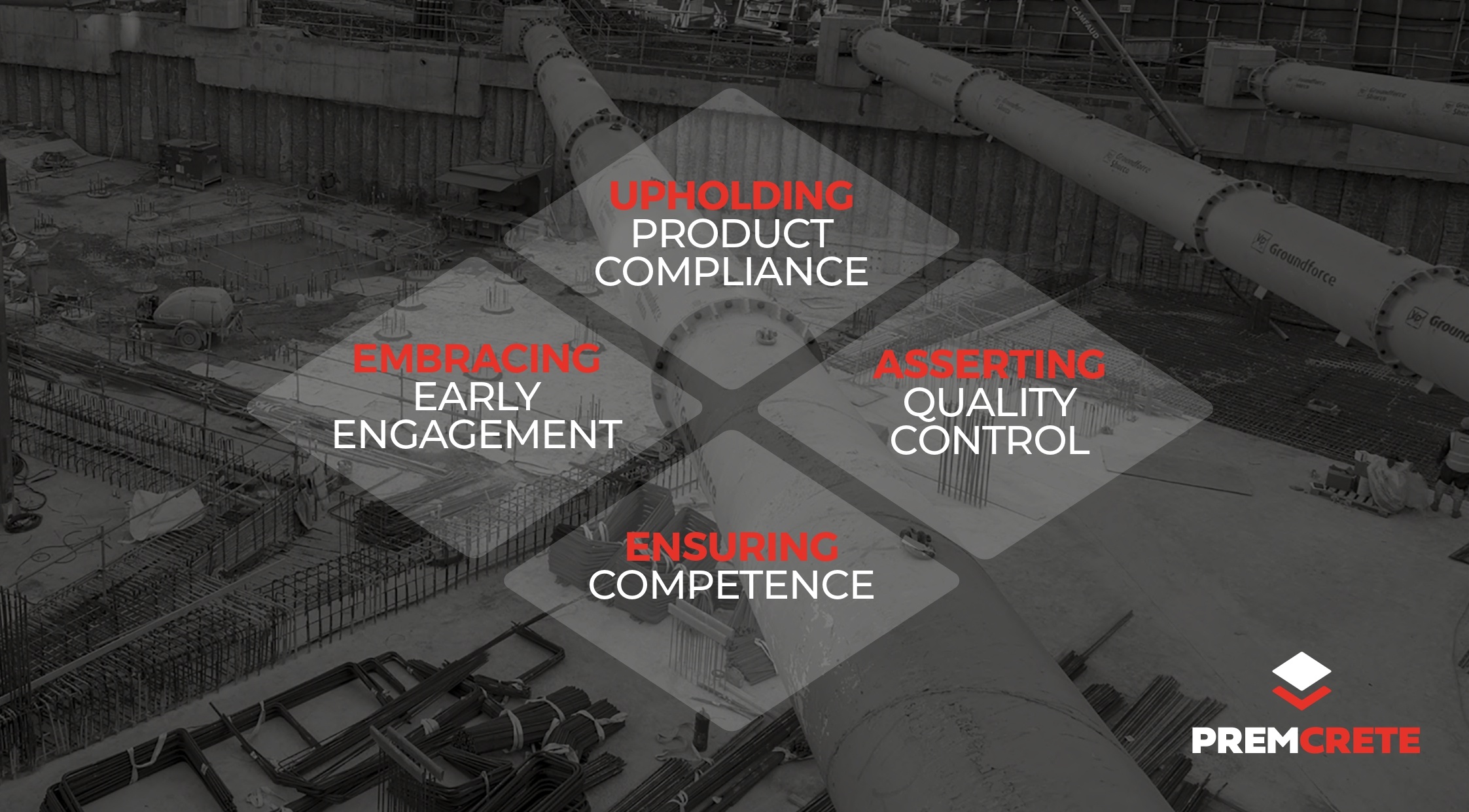

As waterproofing specialists, we understand the importance of addressing specific considerations to finalize a detailed waterproofing strategy. Some crucial factors include:

- Presence of gas risk or hydrocarbons in the soil or water table

- Water table level and risk

- Soil makeup (cohesive or incohesive, drained or poorly drained)

- Waterproofing grades and performance specifications expected by the client

- Type of piles in the basement (secant, contiguous or sheet steel Piles)

- Are there sprinkler tanks or attenuation tanks?

- Are there any lightwell areas?

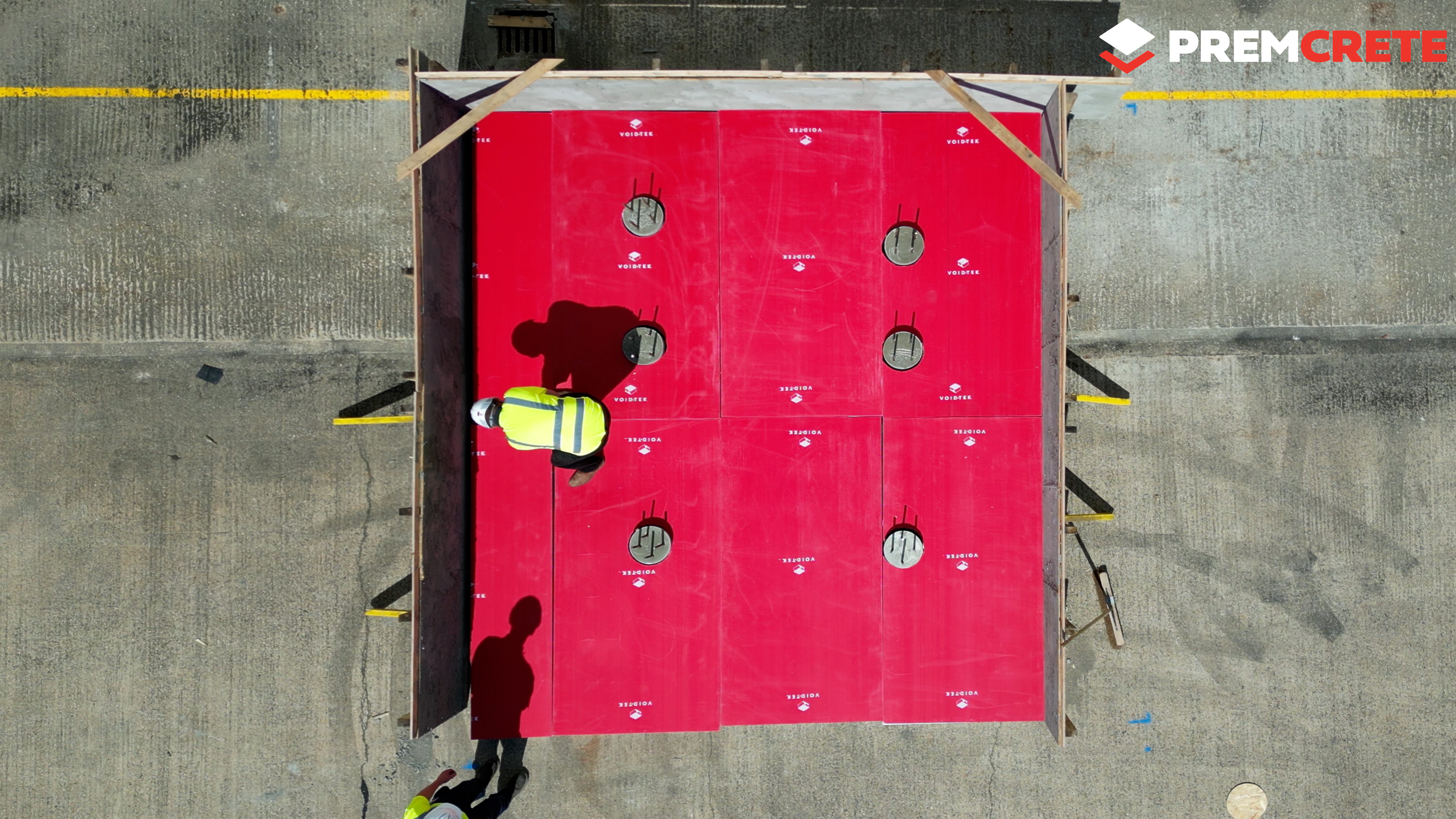

- Are there podium deck areas?

- Is Ground heave required and if so are their details of clay plasticity levels?

Failing to address these considerations can lead to costly mistakes down the line.

- Familiarize yourself with these frequently asked questions

Now to address some frequently asked questions that are asked of us in design meetings, and knowing the answers to these questions can help ensure all stakeholders are informed, and keep the meeting more focused and as brief as possible for the busy construction professionals that will be joining.

Here are five of the top questions we get asked regularly:

Is Premcrete CSSW qualified?

We respond with yes, we have seven members of staff with CSSW qualifications, who are placed across various departments in the company – from management to business development and most importantly the design team.

Does Premcrete have PI insurance, and do you take full design liability?

Yes, we carry £10m cover professional indemnity insurance.

When Premcrete are engaged to undertake a project specific waterproofing design, this would be in the form of a signed engagement and typically a fee would be associated with this. In this scenario we are assuming full design responsibility for the waterproofing and/or gas protection design.

What warranty does Premcrete offer?

We offer a 25-year warranty for the products in their installed state. This warranty covers every part of our products and systems, from the basement box to the edge detailing, podium decks, movement joints, and gas protection where required. In a ground floor slab scenario (without a basement), we offer our own DPM to avoid having a patchwork of warranties between waterproofing the lift pits and damp proofing the main slab.

Are there any services Premcrete don’t offer?

From our CSSW qualified team taking on design responsibility, putting the project on our PI, offering a 25-year warranty, offering training on site, and providing a robust quality management system, through to our in-house remedials team, one might think that that’s quite comprehensive!

However, the only thing we don’t do is provide installation ourselves. However, we do provide training to “self-install” teams – i.e. groundworkers, plus we have a significant network of fully trained specialist installers.

Do you offer a collateral warranty?

Yes – we are willing to sign up to a collateral warranty with a contractor and/or client, subject to reviewing the terms of the contract.

In Conclusion

In conclusion, conducting a productive design meeting requires planning, active participation, and a commitment to addressing key considerations. Remember, the devil is in the details, so ensure you’re well-prepared before attending a meeting.

For more insights on construction best practices and waterproofing solutions, visit Premcrete’s product page and case studies.

-1.jpg)