When designing substructures on contaminated ground—particularly sites with elevated hydrocarbon levels such as petrol, diesel, or solvents—there’s a critical decision to be made that often gets overlooked:

Where should the membrane go—and is the concrete beneath it adequately protected?

At Premcrete, our default recommendation is to specify a pre-applied membrane or hydrocarbon-resistant DPM beneath the slab, ensuring aggressive contaminants stay away from the concrete. However, many clients prefer to place the membrane above the slab for sequencing or practicality reasons.

That choice brings real risk:

If the membrane is above, the concrete beneath is directly exposed to hydrocarbons—and unless it’s correctly specified, long-term degradation will follow.

When Are Hydrocarbons Considered Aggressive?

Hydrocarbons only become problematic at certain concentrations in soil or groundwater. Common TPH (Total Petroleum Hydrocarbons) thresholds are:

- ~1,000 mg/kg for weathered petrol

- ~2,000 mg/kg for diesel or light oils

- ~2,000–4,000 mg/kg for heavy/mineral oils

At or above these levels, expect:

- Free-phase hydrocarbon presence

- VOC vapours

- Direct chemical attack on concrete

That's why you must review your SI report and consult the geotechnical/environmental engineer, confirming whether hydrocarbons or VOCs exceed these thresholds is the first line of defence.

Concrete Alone Isn't Enough

If the waterproofing membrane is placed above the slab, the slab itself must be chemically resistant.

Recommended Concrete Specification

Your concrete must meet:

- Strength class: C40/50

- Chemical resistance: DC-4 (D40) per BS 8500‑1 Table A.1

- Max w/c ratio: 0.45

- Minimum cement content: 400 kg/m³

Key point: Strength (C40) ≠ Chemical resistance (D40). You need both.

Premcrete Systems for Full Protection

To protect concrete from hydrocarbons, VOCs, gas, and water, we recommend an integrated system:

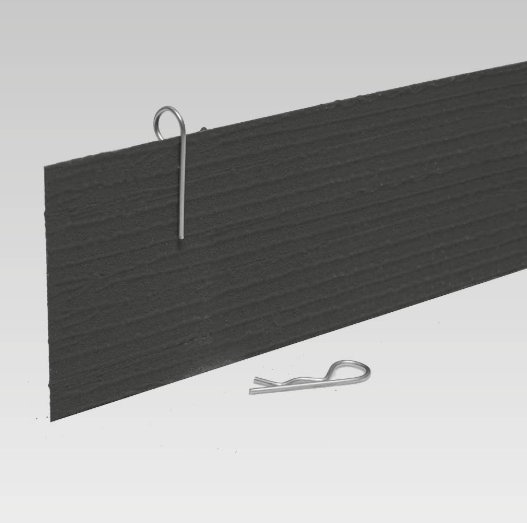

Combiseal Plus™ – Self‑healing, pre‑applied waterproofing

- HDPE membrane with non‑woven geotextile

- Combines self-healing and fully bonded protection

- Ideal for basements, lift pits, and below-ground applications

- High-density polyethylene DPM

- Resistant to gases, VOCs, and hydrocarbons

- Two-part liquid epoxy gas membrane

- Perfect for complex details, upstands, pile heads, pile caps, and avoids the need to wrap pile caps

- Two-component sealing compound

- Provides flexible, durable protection at joints, penetrations, and interfaces

Hydroplug™ – Tri-component penetration sealing system

- Polyester fibre-reinforced foam + hybrid putty + waterproof mortar

- Non‑flammable, solvent‑free, seals water, gas, VOCs and hydrocarbons

Spec & System Checklist

- Check SI report and confirm TPH/VOC levels with engineers.

- If the membrane is above the slab, specify C40/50 + D40 concrete.

- Install Combiseal Plus™ or Hydroprufe 6000™ beneath the slab for belt-and-braces protection.

- Use Hydroprufe LG™ on upstands, pile heads, pile caps and complex detail areas—no wrapping required.

- Seal interfaces with Twinseal GR™ and service penetrations with Hydroplug™.

Final Take

Hydrocarbons aren't just a membrane concern—they can degrade concrete if not properly specified and protected. Protecting the slab from below using products like Combiseal Plus offers the best assurance. If site constraints force the membrane above, upgrading the concrete to D40 and integrating the right product stack from Premcrete is essential.

Let our technical team help you design a fully compliant, hydrocarbon-resilient substructure. We can deliver full spec packs, NBS clauses and submittal documents on request: technical@premcrete.com

-1.jpg)