When it comes to structural waterproofing, specifying the right materials is just the beginning. Too often, we see excellent products let down by poor on-site installation, rushed sequencing, or miscommunication between teams. The result? Latent defects, rework, delays, and costly damage claims—sometimes years after project handover.

That’s why we believe one simple but powerful addition to your waterproofing spec can make all the difference: on-site training by the manufacturer with built-in product familiarisation.

The Problem Most Specs Miss

Architects, engineers, and specifiers are rightly focused on performance, longevity, and compliance. But a spec that only lists materials assumes everything else goes perfectly on site. It assumed the installer's experience, the site's readiness, and the sequencing of trades are all aligned.

In reality, they often aren't.

We've seen time and again that the gap between design intent and installation execution is where waterproofing fails. Not because the materials were wrong, but because they were misunderstood, misapplied, or rushed.

How Site Training Changes the Outcome

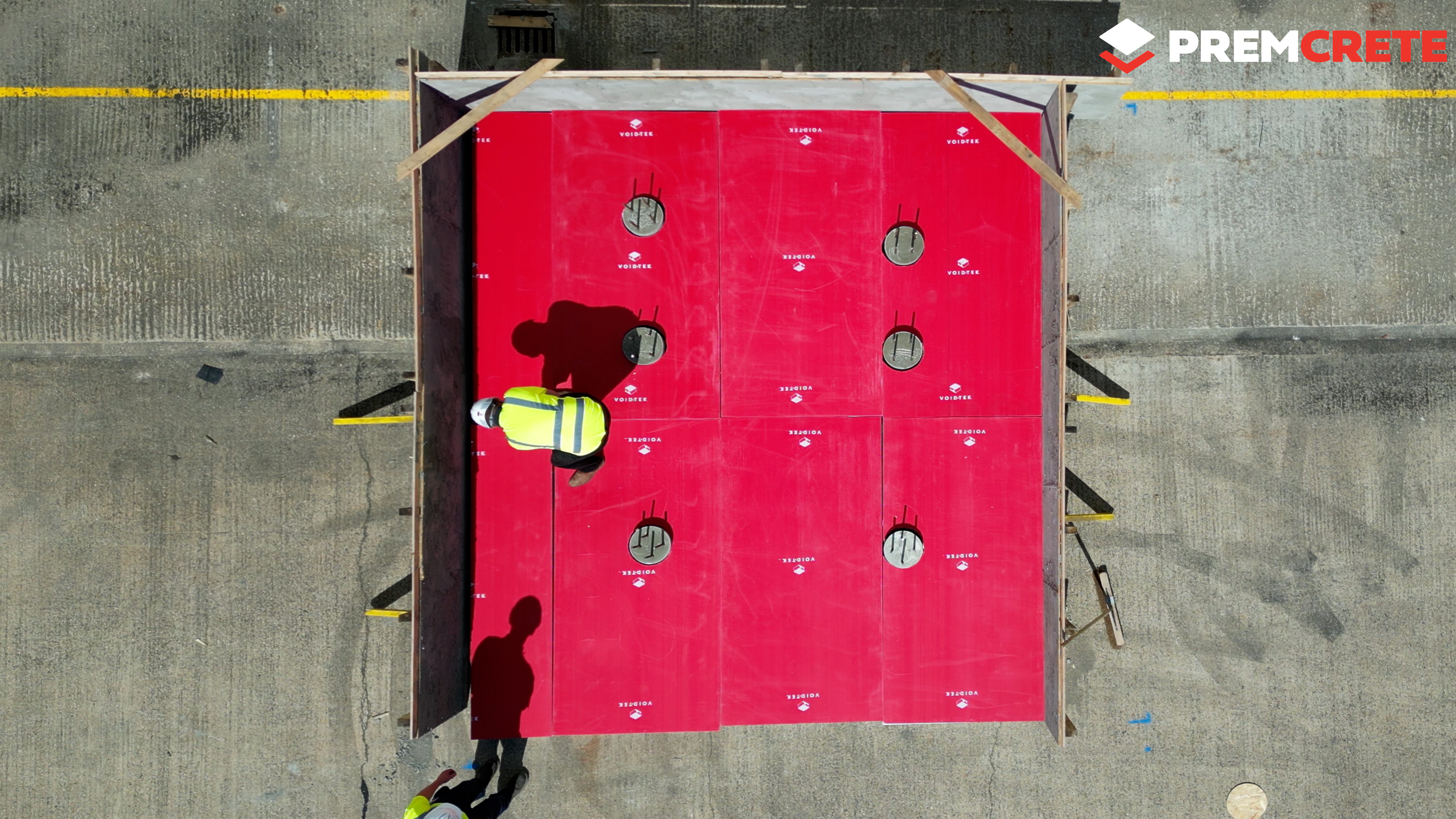

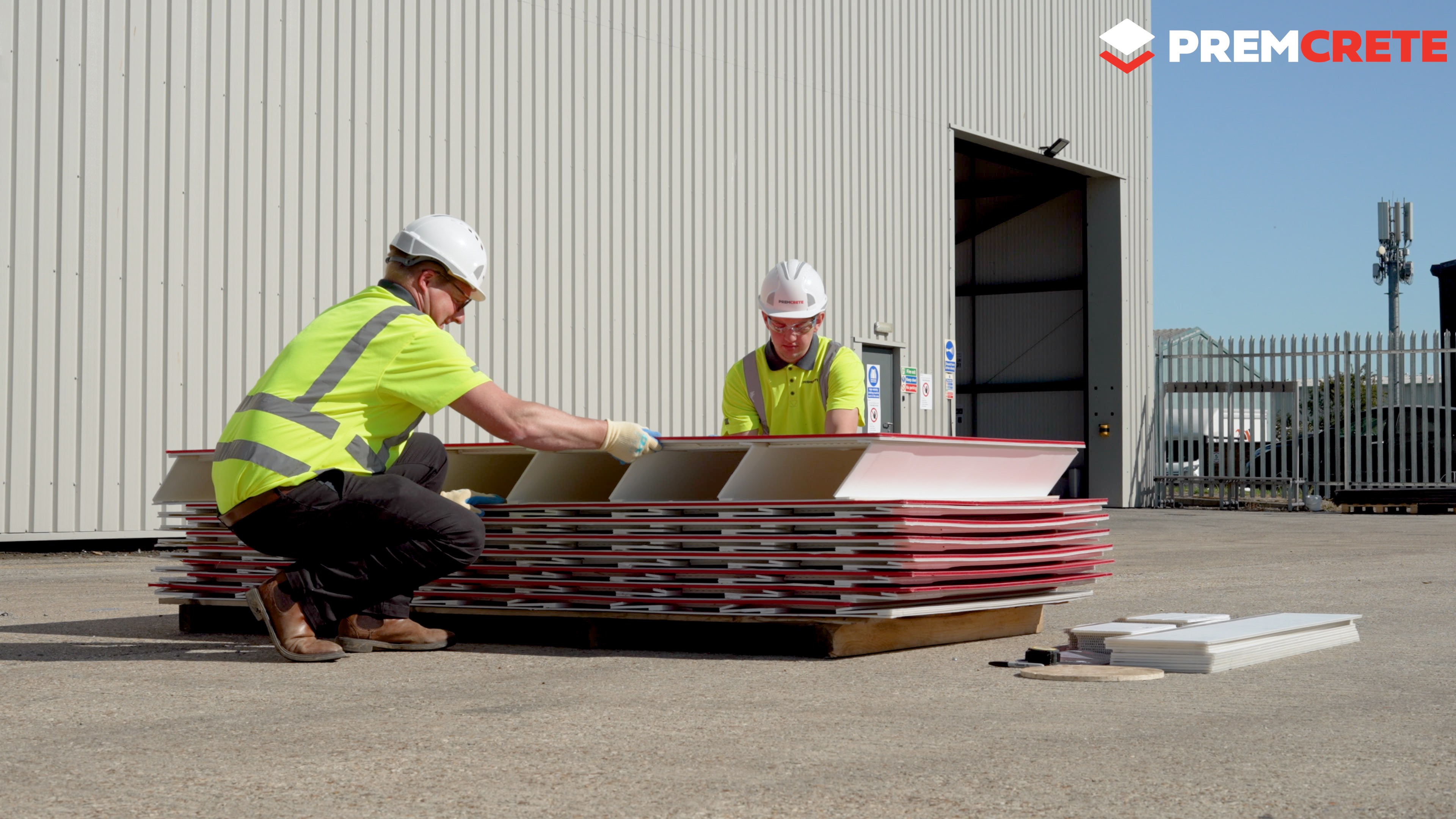

Our site training isn't just a box-ticking exercise. It's a structured, high-impact intervention that gives installers the clarity and confidence they need to get the job right the first time. Central to this is product familiarisation- making sure everyone on site knows how the system works, what to look out for, and how to handle it correctly.

We provide:

- Pre-installation briefings with key subcontractors

- Toolbox talks focused on sequencing, substrate prep and tricky detailing

- On-call technical support for real-time problem solving

- Feedback loops to your design team when something needs flagging

This practical, boots-on-the-ground approach consistently helps:

- Prevent early-stage mistakes

- Speed up install timelines

- Reduce post-install queries and defects

- Build long-term confidence in your chosen waterproofing system

We've Doubled Down on Quality: New Structure, Same Mission

As a manufacturer, we understand that product quality is only half the equation. That's why we've recently streamlined our internal management structure to make support faster and more effective. Our team is small, but every one of us is technical. There's no delays. Just clear answers from experienced people.

We're not just here to deliver boxes of materials. We're here to help you deliver success.

Premtrac: Quality Control You Can See

To make our commitment to quality even more tangible, we've invested heavily in improving Premtrac, our proprietary QC and progress-tracking platform. These updates have been led directly by feedback from site teams, contractors and specifiers to ensure it delivers what projects actually need.

Premtrac allows us to:

- Monitor key installation milestones

- Document site conditions and photographic evidence

- Flag issues for immediate resolution

- Provide specifiers with real-time updates and digital QC records

It's not just a nice-to-have. Premtrac is a living record of the system being installed to spec. That's peace of mind for you, and performance assurance for your client.

How to Build Training and QC into Your Spec

We recommend using a clause like this:

"All waterproofing systems must be installed under manufacturer-led site training and supported by a digital QC platform (e.g., Premtrac or equivalent), including on-site product familiarisation."

This small line makes a big difference. It shifts responsibility from "hope the install goes well" to "we're building success into the process."

Final Thought: Your Spec Is a Statement of Quality

Every word in your spec influences outcomes on site. By including training, product familiarisation and quality control alongside material performance, you raise the standard for everyone involved.

Want to see how we do it? Get in touch with our technical team: projects@premcrete.com

-1.jpg)