When it comes to structural foundations in the UK, the type of concrete slab selected isn't just a structural decision - it has direct impact on how waterproofing is designed, installed, and maintained over a building's life. Whether you're working on residential, commercial, infrastructure or data centre projects, the slab type needs to be considered alongside ground conditions, sequencing, and long-term durability - especially with today's focus on compliance, QA and The Building Safety Act.

Here's a practical overview of the most common slab types used in UK construction - and how Premcrete's waterproofing strategy adapts to suit each.

Raft Slab (Mat Foundation)

Best for: Variable or poor ground conditions, basements. podiums, or where differential settlement is a risk.

A raft slab is a thick concrete slab that spans the full building footprint, distributing loads evenly. It can be used across a wide range of ground conditions - from firm gravels to weak clays - making it a versatile solution in UK soils.

Waterproofing strategy:

- If the slab is below ground, we typically install a pre-applied membrane like Combi-Seal Plus beneath the slab.

- If the raft is ground-level and not part of a basement, a DPM above the slab may suffice.

- Construction joints only require waterbars if the slab is below ground or exposed to hydrostatic pressure.

- No wrapping of reinforcement or pile caps is needed — we coat directly over beams and terminate membranes at the perimeter.

Why it works: Clean, continuous, and easy to detail. This slab type lends itself to both Type A (barrier) and Type B (integral) systems and is ideal when coordinating early-stage waterproofing design.

Piled Slab with Ground Beams / Pile Caps

Best For: Sites with deep made ground, low bearing capacity, or restricted excavation depth — common in city centre or brownfield developments.

This approach uses piles to transfer loads to stable strata, with ground beams and pile caps tying the structure together.

Waterproofing strategy:

- Pre-applied membranes beneath the slab as standard.

- No need to wrap pile caps or beams — instead, we coat over the top of all elements and terminate membranes at vertical junctions.

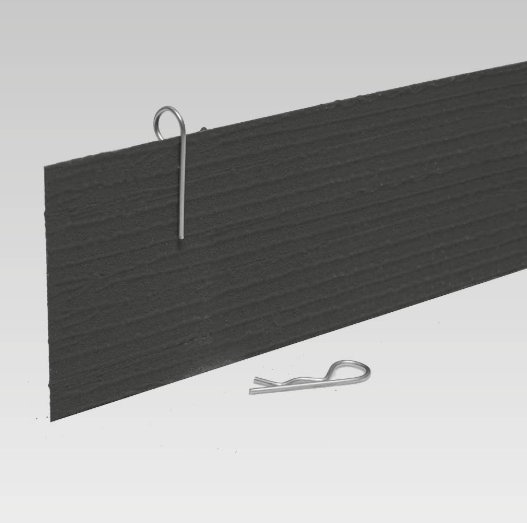

- Hydroprufe LG is used to coat irregular details like pile heads.

- Joint protection through Cemflex VB or injectable hose systems.

Key challenge: More interfaces and irregular details than a raft slab, which increases waterproofing complexity — but with the right design approach and QA via Premtrac, this can be effectively managed.

Ground-Bearing Slab

Best For: Low-rise buildings, garages, commercial sheds, and areas not requiring basement construction.

These slabs sit directly on compacted ground. While structurally straightforward, the waterproofing risks can be underestimated - especially if ground gas, water ingress or clay heave are present.

Waterproofing strategy:

- Loose-laid or pre-applied DPM underneath the slab.

- Optional gas-resistant membranes (e.g. Hydroprufe GR+) where required.

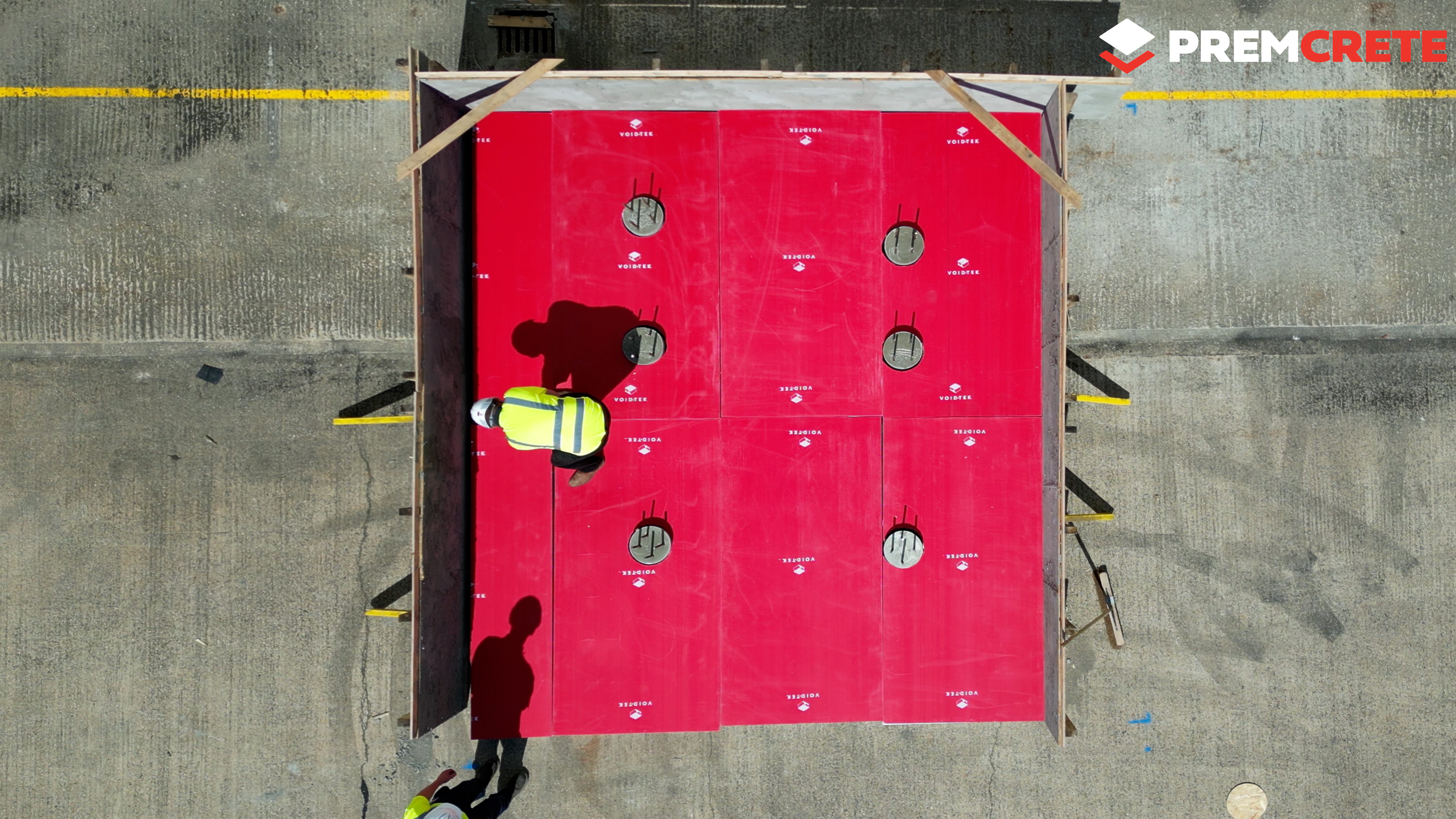

- Incorporate heave protection with products like VOID-TEK in shrink-swell areas.

Note: In accordance with UK regs, DPMs should be continuous with DPCs in walls — something often missed on site.

Suspended Slab (In-Situ or Precast)

Best For: Podium decks, car parks, transfer slabs, or anywhere a slab spans between structural supports.

These slabs don't bear directly on the ground and are often wrongly assumed not to need waterproofing. However, if there's habitable space below, BS 8102 still applies.

Waterproofing strategy:

- Liquid-applied membranes (e.g. Epoflex MMA) or spray-applied polyureas.

- Focus on upstands, terminations, and drainage detailing.

- Typically includes falls to outlets and screed build-up to protect the system.

- Can be overlaid with paving, insulation, or green roofs.

Summary: Slab Type First, Waterproofing Strategy Second

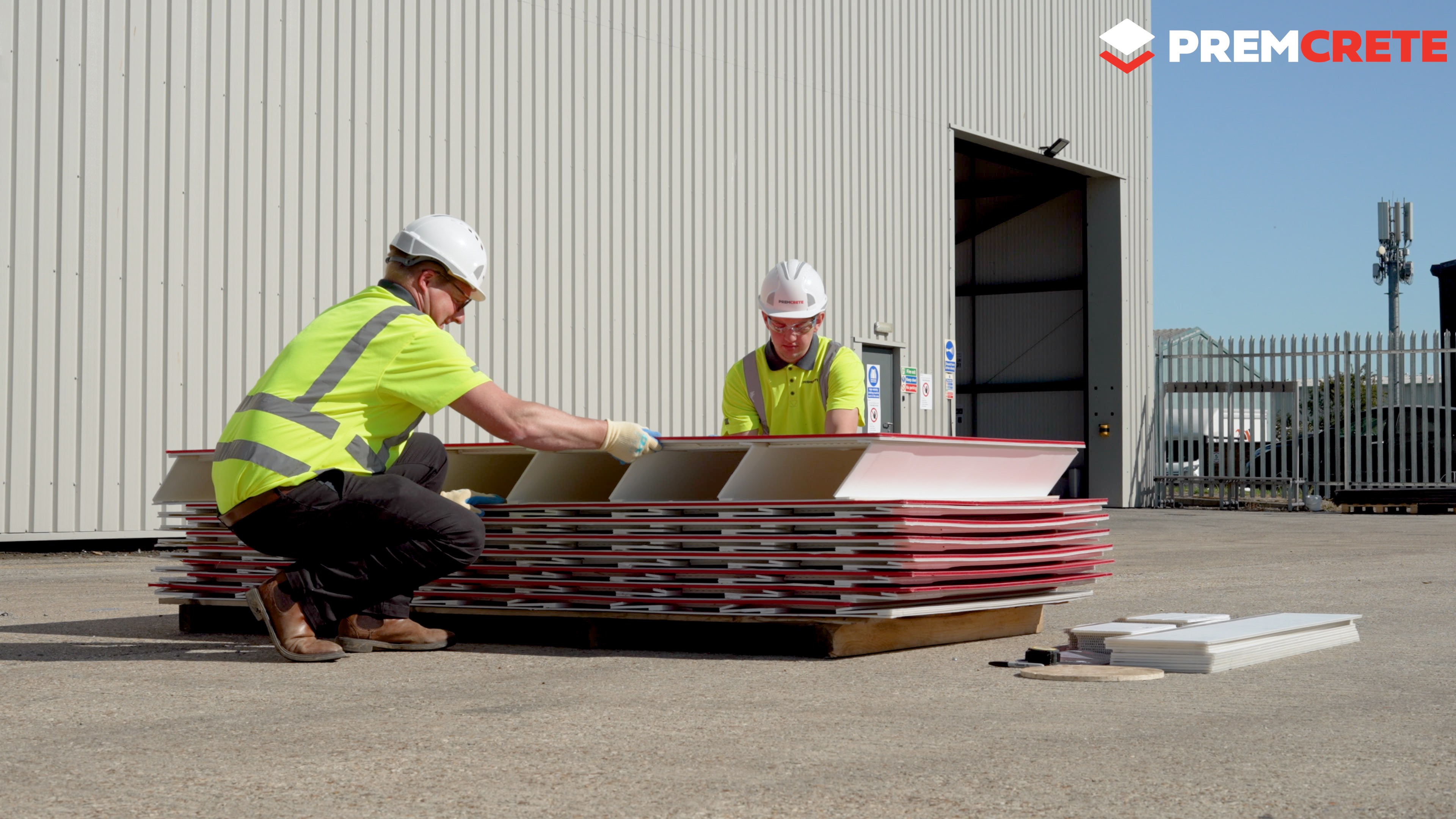

Each slab type has pros and cons. What matters is that your waterproofing design is coordinated with the slab from day one — not treated as a late-stage bolt-on. At Premcrete, we engage early with architects, engineers, and contractors to produce slab-specific, warrantied waterproofing designs that meet BS 8102:2022 and Building Safety Act requirements.

We don’t believe in over-detailing or unnecessary complexity. No wrapping of pile caps. No over-specification. Just practical, robust design with quality control via Premtrac.

Need slab-specific design advice?

Whether it’s raft, piled, or podium, we’ll help you choose the right waterproofing system — and back it with design liability, site support, and full compliance.

Contact our projects teams for early-stage support, CPDs, or design workshops: projects@premcrete.com

-1.jpg)