The Myth of Naturally Waterproof Concrete

It's easy to assume that concrete is waterproof, especially when designed to restrict crack widths to 0.2 mm. While BS 8102:2022 recognises the approach as part of a Type B waterproofing system, it is not a standalone solution for most below-ground structures.

In reality, standard concrete is porous. Moisture can travel through microscopic capillaries, form paths along construction joints, or penetrate cracks caused by structural movement, drying shrinkage, or settlement. Even a 0.2 mm crack (though within design limits) can allow water ingress under pressure over time.

Moreover, warranty providers such as NHBC, LABC, and Premier Guarantee typically do not accept 0.2 mm crack-width-only designs without a recognised waterproof additive, Similarly, Premcrete cannot issue a warranty unless Hydrocrete is included within the concrete mix.

Hydrocrete: Integral Waterproofing with Dual-Action Technology

Hydrocrete is Premcrete’s advanced concrete waterproofing admixture designed specifically for use in Type B systems. It combines:

- Crystalline technology – reacts with water to form insoluble nano-crystals that seal capillaries and micro-cracks

- Hydrophobic pore-blocking agents – repel water and reduce absorption across the entire concrete matrix

This two-phase Dual-AC Technology offers enhanced durability, reduced permeability, and long-term crack-sealing capabilities—even under hydrostatic pressure.

-1.jpg?width=314&height=471&name=ADITL%20July%202.0-2%20(2)-1.jpg)

Crack Width: 0.3 mm and the Misconceptions

BS 8102 references 0.2 mm as a design guideline for waterproof concrete. However, in the presence of a proven waterproofing additive like Hydrocrete, this limit can be extended to 0.3 mm—but context is critical.

There are two key types of cracks to understand:

- Flexural Cracks (through-cracks): Typically caused by structural loads, these cracks pass entirely through the section and pose the greatest risk of water ingress.

- Surface or shrinkage cracks: These are usually the result of drying or plastic shrinkage and may not always extend fully through the section.

Hydrocrete is capable of self-sealing through-cracks up to 0.3 mm, provided the mix is properly designed and placed. Premcrete still recommends limiting crack widths wherever feasible, with careful joint detailing and curing practices.

Waterproofing Grades: How Hydrocrete Supports Compliance

In line with BS 8102:2022, structures below ground are typically required to achieve one of three internal environmental grades:

|

Grade |

Requirement |

Hydrocrete's Role |

|

1b |

Some seepage acceptable but not through structure |

Hydrocrete alone, with waterbars and construction detailing |

|

2 |

Dry environment with occasional damp patches acceptable |

Hydrocrete + a second form of waterproofing (e.g., membrane or cavity system) |

|

3 |

Completely dry, suitable for habitable use |

Hydrocrete + a second form of waterproofing as part of a dual-system approach |

Hydrocrete is effective in reducing both water permeability and vapour transmission, making it suitable as part of a robust solution for Grade 2 and Grade 3 environments when used in combination with Type A or Type C systems. For Grade 1b, it may be used on its own when combined with appropriate waterbars, joint detailing and service penetration sealing.

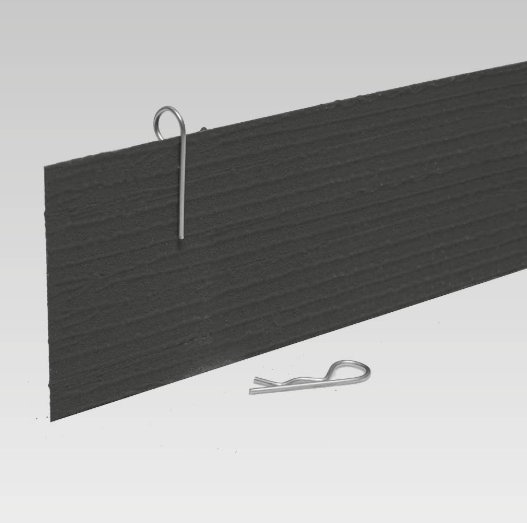

An Alternative Approach: Induced Crack Systems

Some Type B waterproofing strategies on the market rely on the principle of inducing controlled cracks during concrete placement. These systems use specially designed components—installed in the reinforcement before the pour—to predetermine where cracks will occur. After curing, these cracks are accessed through embedded injection channels and permanently sealed with specialist grouts.

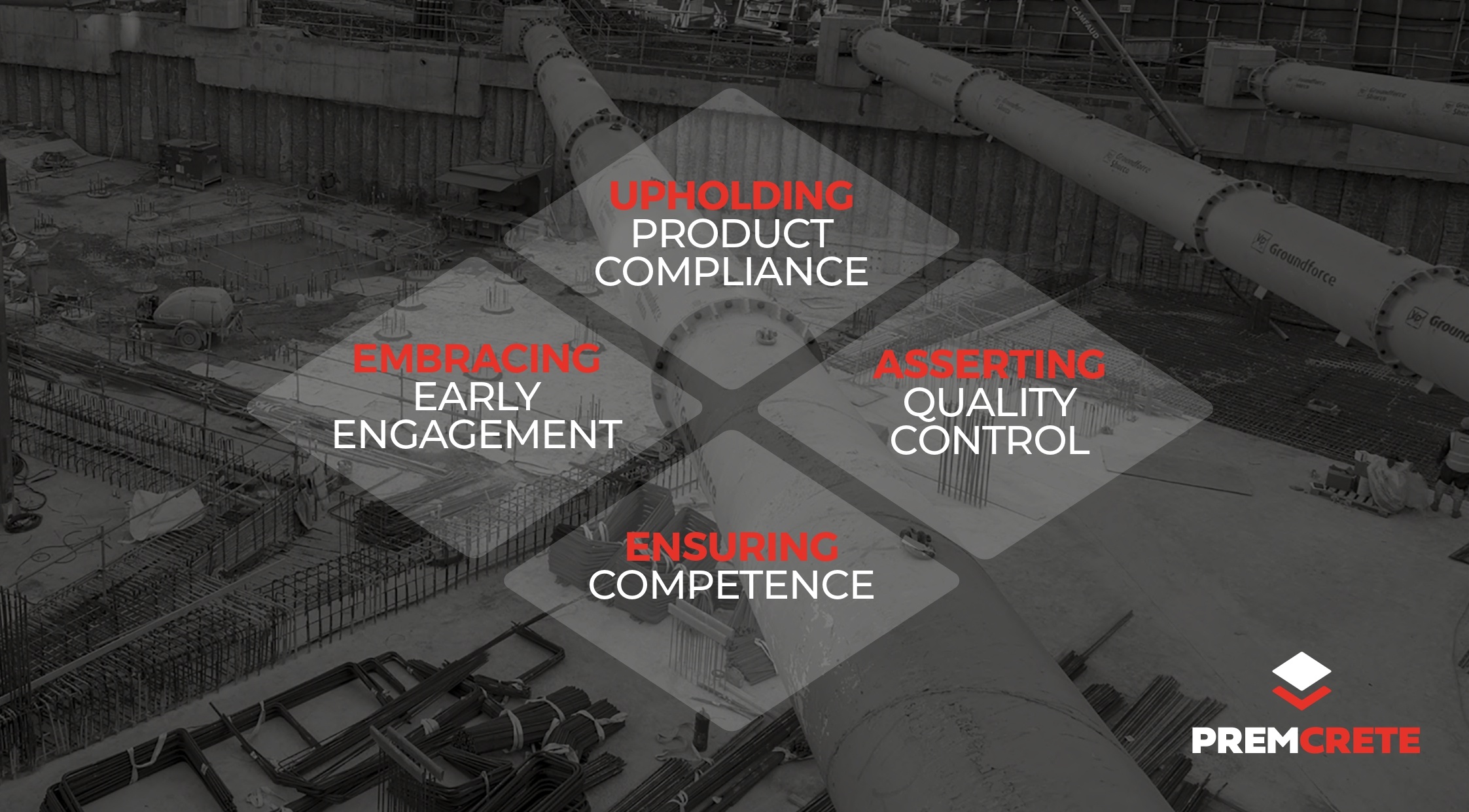

While this method can be effective under the right conditions, Premcrete has chosen not to adopt this approach as our standard Type B system. Following extensive research and real-world evaluation, we found that although controlled cracking and post-injection systems have some benefits (such as enabling larger pour sizes or reducing movement joint requirements), they also introduce a number of limitations:

- They require a third-party specialist installer, which complicates coordination and may affect warranties

- The process typically necessitates standing down the groundworks team, which many contractors would prefer to avoid, especially on fast-track programmes

- The effectiveness of the system relies heavily on accurate placement and execution, and misalignment of the crack-inducing elements could lead to uncontrolled leakage points

- Additional components increase both initial cost and design complexity

At Premcrete we believe in keeping detailing straightforward, removing reliance on post-pour intervention and empowering groundworks and RC frame teams to self-install our Hydrocrete waterproofing system without specialist support.

That said, we do recognise that certain projects—particularly those involving sheet piles, extremely high water tables, or complex geometries—may benefit from added redundancy. For such applications, Premcrete can supply injectable hose systems as a belt-and-braces option. These provide additional assurance at construction joints or difficult transitions, and can be used alongside Hydrocrete as part of a risk-based design approach.

Test-Backed Performance

Hydrocrete's technical performance has been independently verified:

- Water permeability: 3.84× lower than conventional concrete

- Vapour permeability: 3.9× lower

- Crack healing: Up to 0.3 mm

- Chloride-free and corrosion-resistant

- Lightweight dosing: Only 1.75 kg/m³ using pre-measured, water-soluble bags

- Carbon reduction: 11.5 kg CO₂e saved per bucket

This means less risk, lower maintenance, and stronger compliance with sustainability targets.

Conclusion: Concrete is the Start - Not the Solution

Waterproof concrete by design alone will not meet the requirements of most modern below-ground structures, especially where durability, insurance compliance, and client expectations demand full watertight performance.

By using Hydrocrete, specifiers gain a certified, warranty-backed solution for watertight concrete that stands up to pressure—literally and legally. When paired with a second form of waterproofing where required, Hydrocrete forms the foundation for dry, durable, and compliant below-ground spaces.

Want Technical Guidance?

Premcrete’s team provides full mix design support, detailing consultation, and warranty-backed system specifications. Contact us to ensure your next basement or substructure meets performance and compliance goals from the start: technical@premcrete.com

-1.jpg)