Know the difference, avoid duplication, and make the right call for your site.

Many below-ground construction projects require either waterproofing, gas protection—or both. However, understanding when each is needed, and how their costs compare, can make a significant impact on your budget, construction sequencing, and compliance strategy.

In this guide, we explain the key differences between waterproofing and gas protection systems, compare their typical costs, and highlight how integrated solutions can reduce labour, simplify detailing, and minimise long-term risk.

What's the Difference Between Waterproofing and Gas Protection?

While they may appear similar in application, gas protection and waterproofing systems serve distinct purposes:

- Waterproofing (as defined by BS 8102:2022) is designed to resist water ingress and manage hydrostatic pressure.

- Gas protection (per BS 8485:2015 + A1:2019) is required where ground gases such as methane, carbon dioxide, or radon are present.

- VOC / Hydrocarbon protection is needed on contaminated land where substances like diesel, petrol, or volatile organic compounds may be present.

A site investigation report (SIR) will determine whether waterproofing, gas protection, or VOC protection is needed. Not all sites require both—but when they do, selecting the right system combination is critical to avoid sequencing issues, duplicated layers, or compliance failures.

Membrane Cost Comparison: Waterproofing vs Gas Protection Systems

|

System Type |

Protection Level |

Typical Supply & Install Cost (per m²) |

Example Products |

|

Damp Proof Membrane |

Damp proofing only |

£10 |

|

|

Damp proofing & Gas |

£13 |

Hydroprufe 9000 |

|

|

Damp proofing, Gas & VOC protection |

£14 |

Hydroprufe 6000 |

|

|

Pre-applied Membrane |

Waterproofing only |

£32 |

|

|

Waterproofing & Gas |

£36 |

||

|

Waterproofing, Gas & VOC |

£37 |

||

|

Self-adhesive Membrane |

Waterproofing only |

£42 |

|

|

Waterproofing & Gas |

£45 |

||

|

Liquid-applied Membrane |

Waterproofing only |

£48 |

|

|

Waterproofing, Gas & VOC |

£50 |

Prices include taped joints where required but exclude protection board.

Taped vs Welded Joints - Labour Cost Comparison

While the labour approach for taped and welded joints differs, the overall cost and efficiency often balance out. Taped joints are typically faster and simpler to install, making them ideal for standard DPMs and pre-applied membranes. Welded joints, while requiring more specialist labour and equipment, provide a continuous seal that is often preferred on sites with VOCs or hydrocarbon contamination.

For larger areas, welded systems may even prove more economical due to the absence of tapes and reduced overlap detailing. Ultimately, the choice depends on site conditions, warranty requirements, and membrane type.

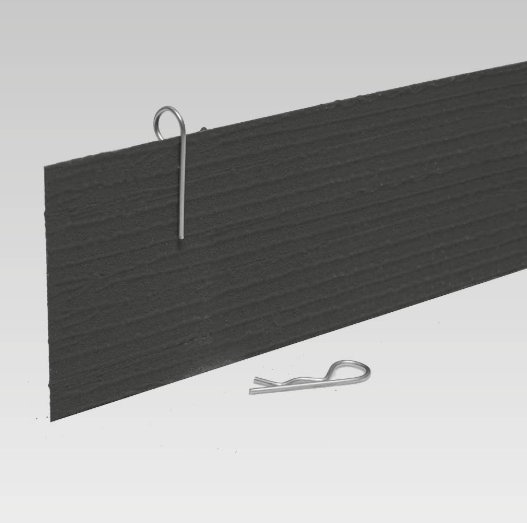

Taped Joints

- Lower labour cost

- Faster installation

- Suitable for DPMs and pre-applied membranes

- Can be installed by non-specialist labour

- Relies on tapes for sealing overlaps

Welded Joints

- Requires trained operatives and specialist welding kit

- Provides a continuous, monolithic seal

- Preferred on VOC-affected or hydrocarbon-contaminated sites

- Sometimes required by warranty providers (e.g. NHBC)

- Can be more cost-effective on large areas due to no tape requirements

Site Conditions: The Key Risk Factor

Contaminated Land & VOCs

Sites affected by hydrocarbons, methane, radon, or VOCs often require VOC-rated membranes and sealed joints—raising both material and installation costs. In severe cases, additional ground investigation or laboratory testing may be needed.

In some scenarios, land remediation (e.g., removing or treating contaminated soils) may be more cost-effective than installing high-spec barrier systems. It’s worth weighing the cost of remediation vs. designing around the risk, particularly when VOC protection and third-party verification are involved.

Hydrostatic Pressure & Basement Depth

Deeper excavations or high water table zones introduce more hydrostatic pressure, typically necessitating Type C cavity drainage systems with channels, membranes, and sump pumps. These systems:

- Must be installed by a specialist (not suitable for self-install)

- Often rule out the use of waterproof concrete additives

- Can increase installation time and programme complexity

If self-installation is preferred, this may limit your system options and should be considered during early-stage budgeting and design.

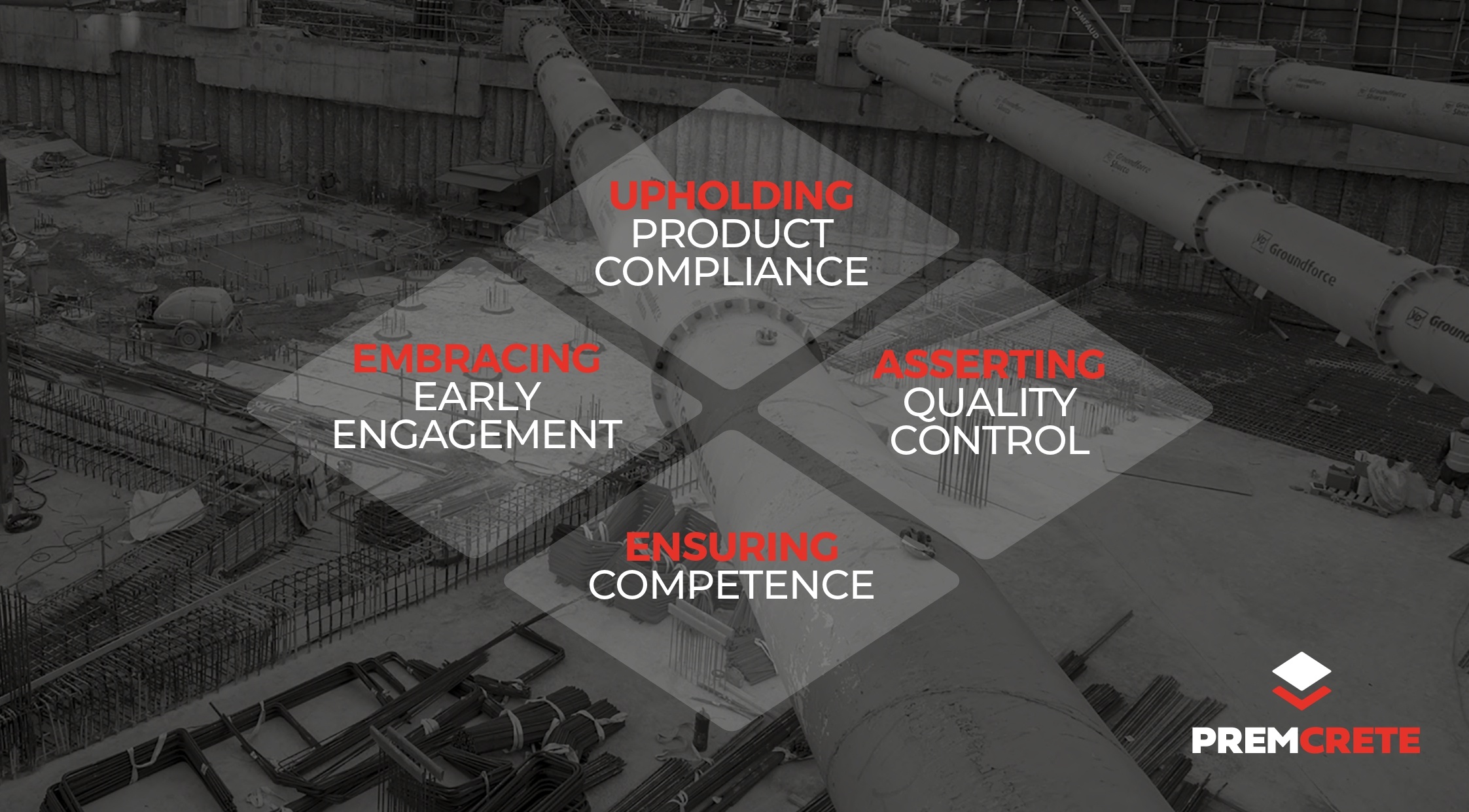

Third-Party Inspections - A Hidden but Essential Cost

When gas protection systems are required, CIRIA C735 mandates independent verification by qualified inspectors to ensure installation integrity. The frequency of visits will be determined by a number of factors as outlined in CIRA C735 – Complexity of Design, Number of Plots / Buildings, Competency of Installation Work Force and Gas Risk Regime.

Here is an approximate guide:

- Inspection cost: £500–£800 per visit

- Complex sites with high gas risk: 1 visit per 100 m²

- Simple layouts with low gas risk (e.g., large sheds): 1 visit per 1,000 m²

These costs are often missed in early budgets but are crucial for warranty approval and regulatory compliance—particularly when VOCs or hydrocarbons are involved.

Detailing - The Hidden Complexity That Affects Cost and Compliance

Detailing around pile caps, kicker joints, service penetrations and transitions often drives up cost and complexity. If not planned early, poor detailing can lead to:

- Delays during installation

- Failed third-party inspections

- Increased material wastage

- Long-term leakage or vapour ingress

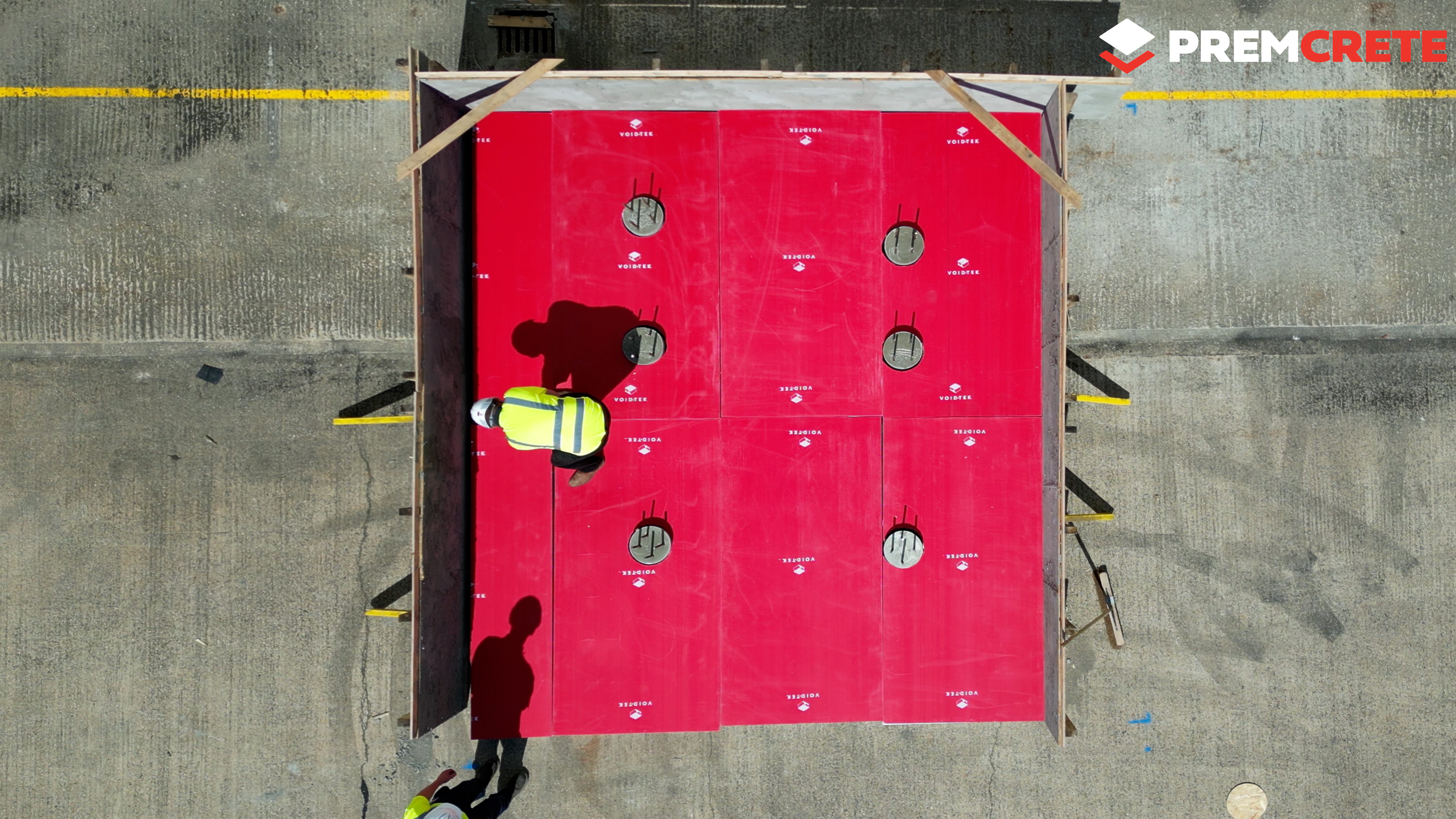

Pile Heads and Slab Detailing

When membranes are installed beneath the slab, pile head detailing becomes a major cost centre. Wrapping each pile cap with membrane or liquid coating can be time-consuming and labour-intensive.

While installing membranes above the slab is sometimes done at ground floor level, it is not recommended in VOC or hydrocarbon environments. These contaminants can migrate through cracks or voids in concrete, rendering the barrier ineffective.

Premcrete Solutions for Detailing Efficiency

Premcrete offers a suite of products designed to streamline detailing, reduce labour, and maintain compliance:

- Maxiprufe Plus (pre-applied membrane)

Forms a continuous bond with the concrete pour, eliminating taping and simplifying junctions around kicker joints, allowing direct application to piles, and more efficient ways of detailing to capping beams. - Hydroprufe LG (liquid-applied epoxy)

Designed for complex details such as pile heads, pipe penetrations, and vertical transitions.

👉 Avoids the need to wrap pile caps, reducing labour and simplifying sequencing—particularly on VOC-contaminated sites. - Twinseal GR (brush-applied sealant)

A two-component VOC- and gas-resistant compound for critical termination interfaces such as pile heads, and challenging connection zones such as horizontal-vertical wall joints.

Provides robust protection where taped or welded membranes alone may be vulnerable.

Integrated Systems Are Often More Cost Efficient

Installing separate waterproofing and gas membranes can double labour time, increase material waste, and raise the risk of detailing errors. Premcrete’ s COMBI-SEAL and COMBI-SEAL PLUS systems offer a streamlined, pre-applied dual membrane that provides:

- Type A waterproofing

- Full gas protection (including VOC resistance in COMBI-SEAL PLUS)

- Reduced detailing complexity and inspection costs

What Happens If You Choose the Wrong System?

- Compliance failure – Non-compliant systems can delay PC or void warranty approvals

- Rework – Mis-sequenced membranes may need to be removed and reapplied

- Warranty risk – NHBC and other providers may reject poorly validated systems

- Health & legal liability – Incorrect gas protection can expose future occupants to serious risk

Design Strategy = Smarter Budgeting

The best way to manage cost is to align your protection strategy with your site’s actual risks—early.

Premcrete supports main contractors and design teams with:

- Site-specific feasibility reviews

- Design strategy drawings

- Budget comparisons (e.g. taped vs. welded)

- Compliance support for BS 8102:2022 and BS 8485:2015+A1:2019

By working with Premcrete early, you’ll avoid duplication, reduce installation risk, and ensure compliance across both waterproofing and gas protection disciplines.

Not Sure If You Need Waterproofing, Gas Protection, or Both?

Let Premcrete help you review your site investigation report and recommend a compliant, cost-effective solution—complete with budget guidance and system options.

-1.jpg)