Ground heave is a significant challenge in substructure construction, caused by expansive clay soils that can lead to damaging structural movements. For structural engineers and project managers, protecting the integrity of your build while keeping costs and environmental impact low is essential. Traditional void formers, made from polystyrene. often fall short by incurring high transport costs, excessive storage needs, and a tendency to break and crumble —resulting in waste and unpredictable expenses.

Understanding Ground Heave And Its Impact

Ground heave occurs when soil expands due to moisture changes, putting pressure on foundations and substructures. The risks include:

Structural Damage: Expanding soils can lead to cracks and shifts, compromising the integrity of the building.

Increased Maintenance: Repairing damage can disrupt project timelines and escalate costs.

Reduced Project Lifespan: Persistent heave can shorten the overall durability of a structure.

For these reasons, effective ground heave protection is non-negotiable in modern construction projects.

Challenges With Traditional Polystyrene Void Formers

Conventional void formers have long been used to create a protective gap beneath structures. However, they bring several inefficiencies:

High Transport & Storage Costs: Bulky systems often require multiple loads and significant onsite space.

Vulnerability to Damage: They are easily damaged during handling, leading to increased waste and higher overall costs.

Environmental Concerns: The disposal of polystyrene waste not only increases costs but also harms the environment

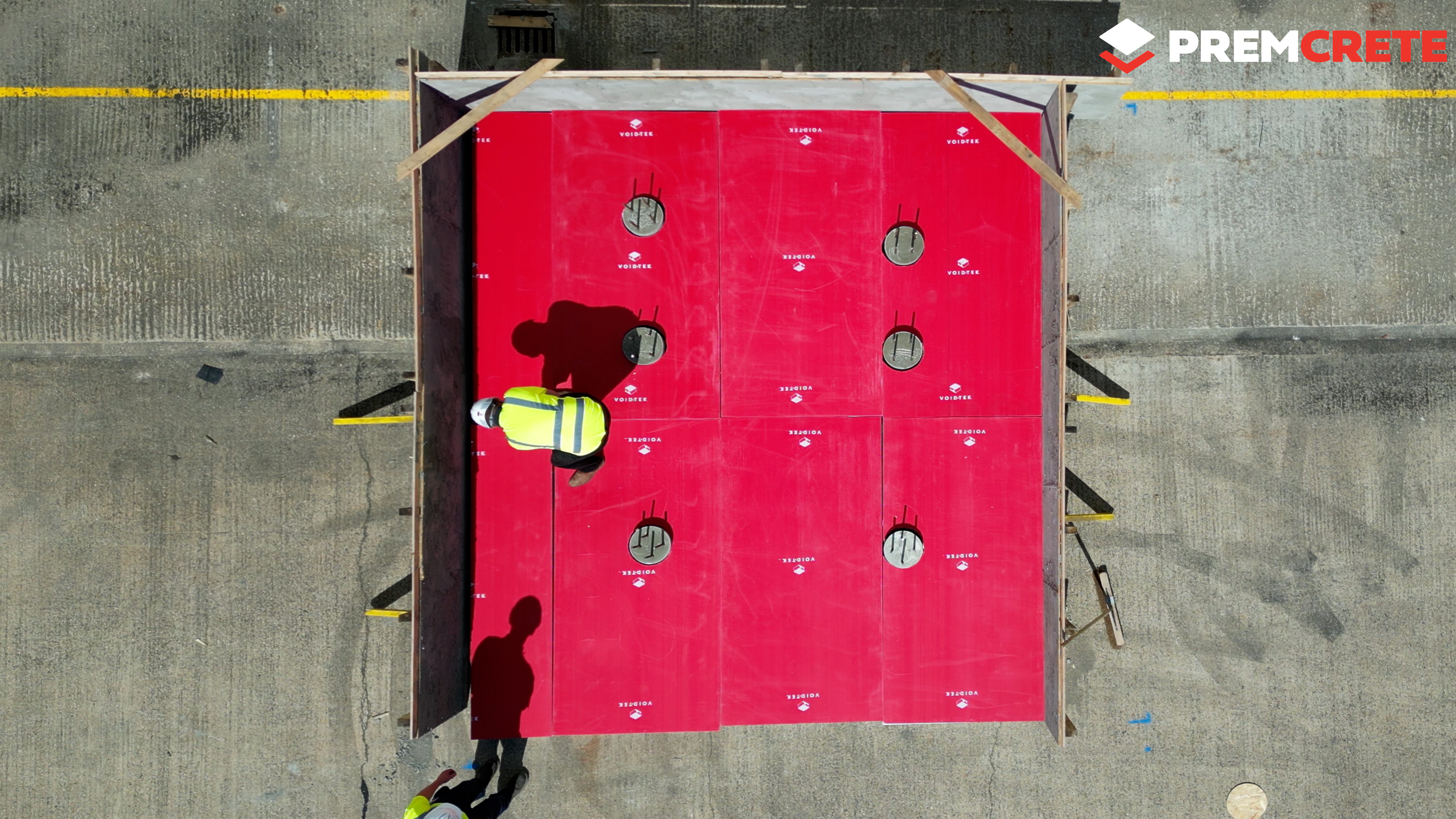

Introducing VOID-TEK: The Innovative Void Former

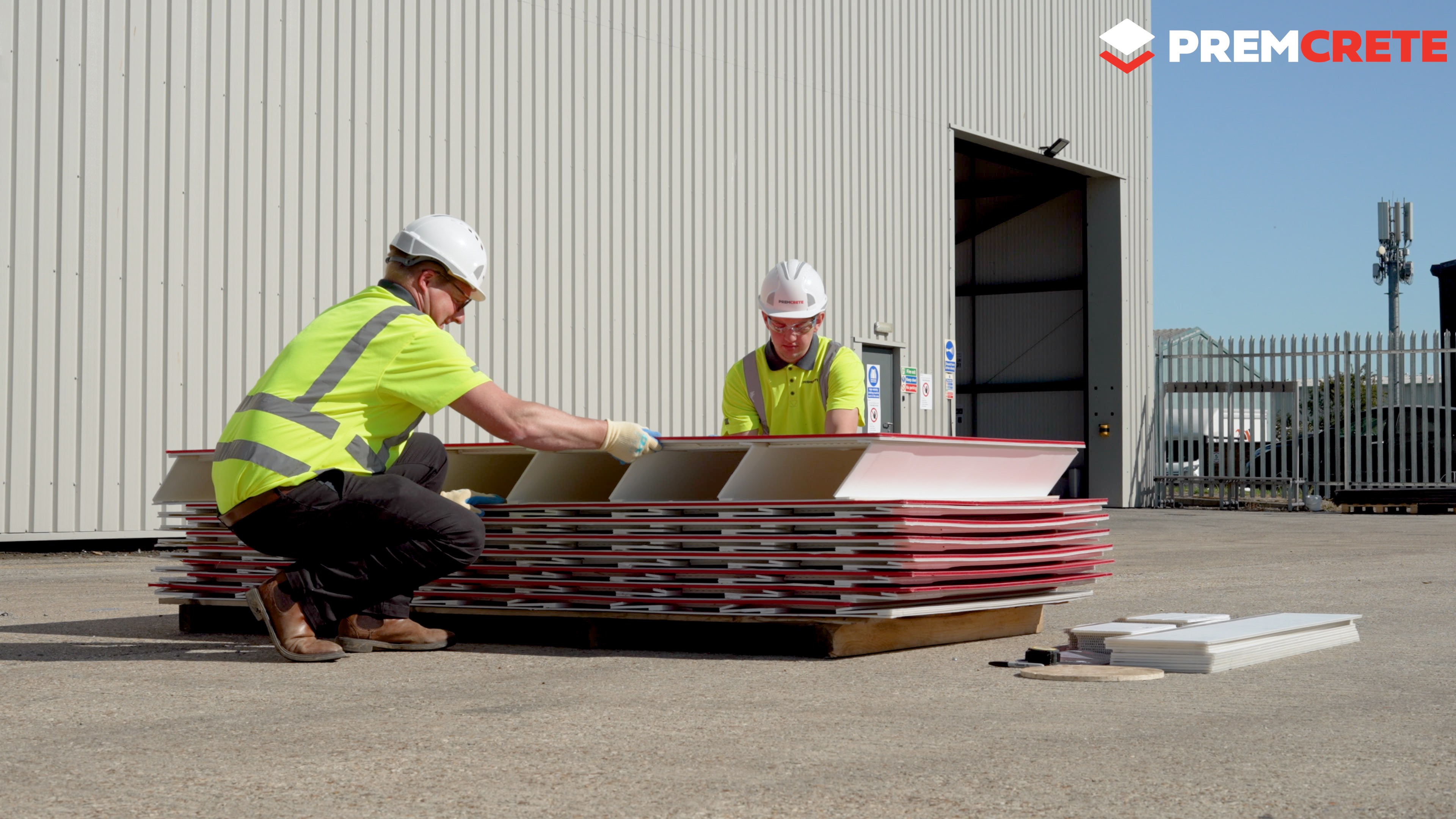

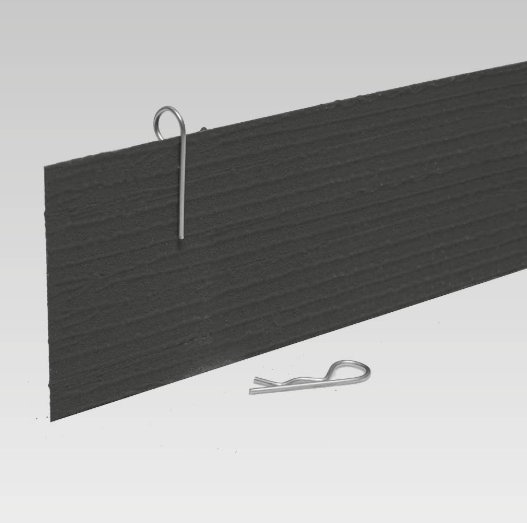

Premcrete’s VOID-TEK system is engineered from high-strength polypropylene fluted board—a game changer in ground heave protection. Its flat-packed, collapsible design and polystyrene-free construction offer multiple benefits:

Robust Durability: The material resists damage underfoot, significantly reducing waste.

Ease of Installation: VOID-TEK is lightweight and can be easily cut with a compact Stanley knife, speeding up onsite modifications.

Customisable Solutions: It can be ordered to specific dimensions, ideal for use beneath reinforced concrete ground beams and pile caps.

Cost Efficiency: Reduced transport, storage, and labour costs lead to a more predictable project budget.

Sustainable Performance: Without harmful polystyrene, VOID-TEK boasts a lower environmental impact and reduced emissions.

Real-Life Client Feedback

Our clients have experienced the benefits of VOID-TEK first-hand. Here’s what they had to say:

🔺 300𝘮² of VOID-TEK fits on just two pallets – "𝘙𝘢𝘵𝘩𝘦𝘳 𝘵𝘩𝘢𝘯 𝘢 𝘸𝘩𝘰𝘭𝘦 𝘭𝘰𝘳𝘳𝘺 𝘭𝘰𝘢𝘥 𝘵𝘩𝘢𝘵 𝘵𝘢𝘬𝘦𝘴 𝘩𝘰𝘶𝘳𝘴 𝘵𝘰 𝘰𝘧𝘧𝘭𝘰𝘢𝘥."

🔺 "𝘓𝘪𝘨𝘩𝘵𝘸𝘦𝘪𝘨𝘩𝘵 & 𝘦𝘢𝘴𝘺 𝘵𝘰 𝘪𝘯𝘴𝘵𝘢𝘭𝘭 – 𝘳𝘦𝘥𝘶𝘤𝘪𝘯𝘨 𝘩𝘢𝘯𝘥𝘭𝘪𝘯𝘨 𝘵𝘪𝘮𝘦 𝘰𝘯 𝘴𝘪𝘵𝘦."

🔺 "𝘔𝘰𝘳𝘦 𝘦𝘧𝘧𝘪𝘤𝘪𝘦𝘯𝘵 𝘵𝘩𝘢𝘯 𝘵𝘳𝘢𝘥𝘪𝘵𝘪𝘰𝘯𝘢𝘭 𝘢𝘭𝘵𝘦𝘳𝘯𝘢𝘵𝘪𝘷𝘦𝘴."

These testimonials underscore how VOID-TEK enhances project efficiency and offers real cost savings in transport, installation, and waste management.

The VOID-TEK Advantage For Your Projects

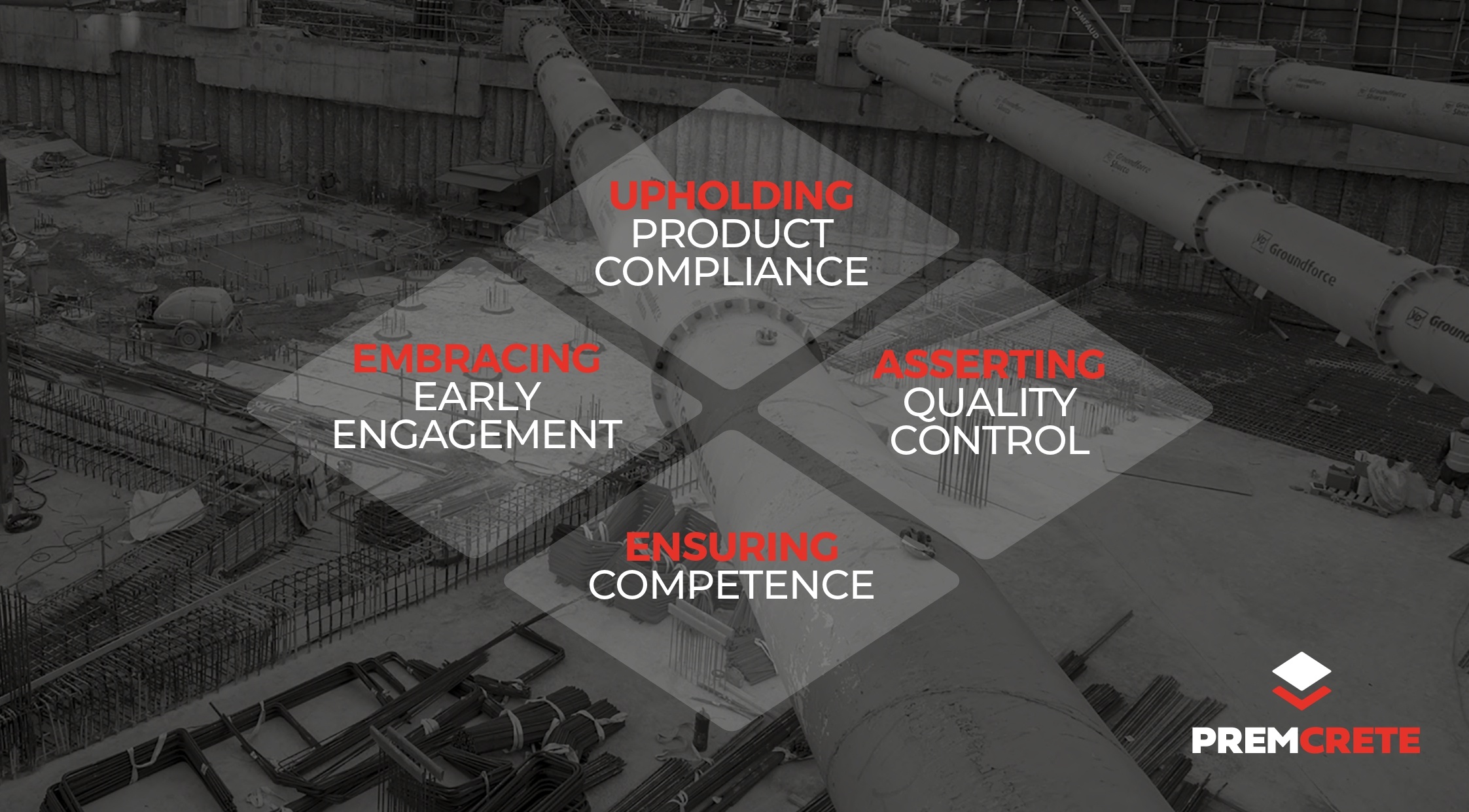

VOID-TEK meets NHBC void requirements, ensuring it adheres to the highest quality and safety standards in the construction industry. Its superior resilience and ease of handling directly translate into:

Faster Installations: Minimising onsite delays and accelerating project timelines.

Lower Operational Costs: Reduced labour, transport, and waste disposal expenses.

Sustainable Construction Practices: A solution that supports environmental goals without compromising performance.

Make your next project more efficient, cost-effective, and environmentally friendly. Contact Premcrete today to learn more about switching to VOID-TEK—our revolutionary ground heave protection solution that’s setting new industry benchmarks: sales@premcrete.com

-1.jpg)