The regulatory landscape for construction in the UK has significantly evolved, particularly with the implementation of the Building Safety Act (BSA) 2022 alongside the established CDM (Construction Design & Management) 2015 regulations. Together, these frameworks place a heightened emphasis on client accountability, duty holder competence, and lifecycle safety. But what does this mean in practice, especially for specialist areas like structural waterproofing and gas protection? In this blog, we break down the essentials of CDM client duties, how they intersect with the BSA, and illustrate the points with real-world examples from our experience in the field.

CDM 2015: Understanding Client Duties (Regulation 4)

Clients play a central role in ensuring construction projects are compliant and safe from concept through to completion. Under Regulation 4 of CDM 2015, the client holds non-transferable legal duties, including:

- Allocating sufficient time and resources

- Developing a clear client brief

- Making formal appointments of Principal Designer (PD) and Principal Contractor (PC) in writing

- Ensuring the provision of accurate pre-construction information (PCI)

- Reviewing the Construction Phase Plan (CPP)

- Maintaining welfare facilities in line with Schedule 2

- Ensuring F10 notifications are made and kept up to date

- Monitoring and verifying the arrangements throughout the project

- Retaining and distributing the Health and Safety File

This isn’t about clients doing all the work themselves but about making sure it gets done and documented. Clients can appoint competent advisors to assist them, but the legal responsibility always remains with them.

Real-World Example: Waterproofing in Multi-Storey Residential Projects

Let’s say a client is overseeing the construction of a 12-storey apartment block. As part of the design, a waterproofing strategy must be developed for the basement, podium deck, and balconies. Appointing a Principal Designer with CSSW-accredited expertise in structural waterproofing is essential. The client must:

- Ensure the PD understands the expectations set out in the client brief, including maintenance and access requirements

- Provide pre-construction info such as ground condition surveys, flood risk assessments, and previous site history

- Review the design risk register to ensure issues like water table fluctuation, hydrostatic pressure, and membrane continuity are addressed early

Without this level of involvement, waterproofing details may be vague or inconsistent, leading to post-construction disputes, warranty claims, or worse—water ingress affecting future occupiers.

CDM Compliance Meets the Building Safety Act

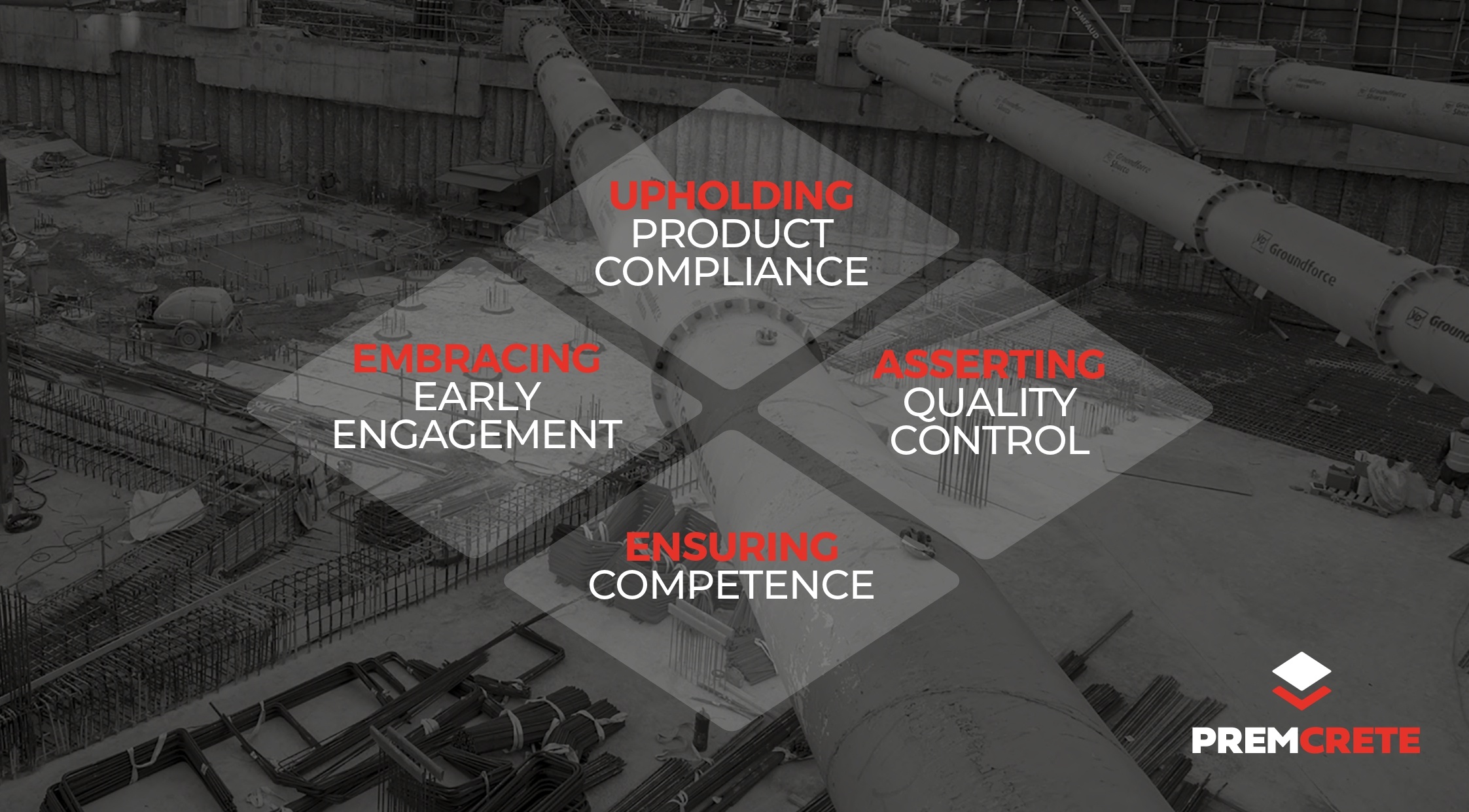

The BSA 2022 introduces a cultural shift: moving from reactive safety measures to proactive, demonstrable competence. Key intersections between CDM and BSA include:

- The need for named individuals on the F10 form (not just organisations)

- Stronger evidence of duty holder competence (e.g. CSSW qualifications for waterproofing design)

- Early coordination before Gateway 2 submissions, especially for high-risk buildings (HRBs)

- Maintaining a "Golden Thread" of information across the building lifecycle

In our work, we often see clients struggle with documentation when it comes to waterproofing and gas protection systems. That’s why we developed our own quality control portal, Premtrac, to record and share inspection reports, training logs, and site photos. These records now help clients satisfy both CDM and BSA requirements.

Common Pitfalls: Misunderstanding Roles and Responsibilities

Many clients still believe that duties like preparing the F10 or reviewing the CPP fall to the PD or PC by default. This misunderstanding can lead to legal exposure. Regulation 9 of CDM even prohibits designers from starting work unless they are satisfied that the client understands their duties.

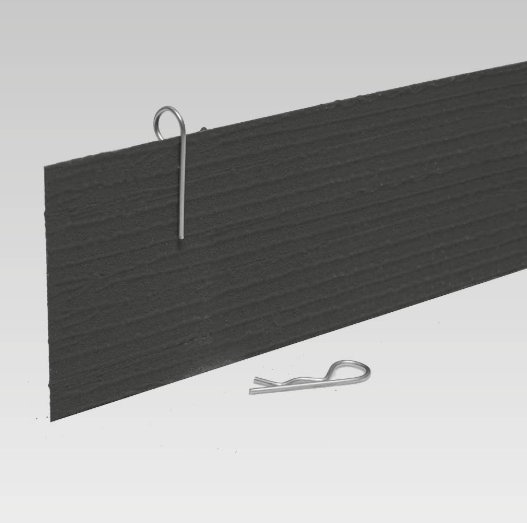

In gas protection schemes—often required on contaminated or brownfield sites—the need for detailed design coordination becomes even more important. For example:

- The client must ensure that PCI includes ground gas risk assessments and site investigation data

- A qualified specialist must be appointed to design the membrane layout and detailing, ensuring buildability and inspection access

- Monitoring arrangements (e.g. site inspections, air tightness testing) must be part of the CPP

HSE Focus: Pre-Construction is Key

The Health and Safety Executive (HSE) has shifted more attention to the pre-construction phase, reflecting the belief that most design risks and opportunities for improvement arise early. This is especially relevant in waterproofing and gas protection, where design decisions significantly impact build sequencing, inspection strategies, and long-term performance.

For instance, a podium deck waterproofing solution using Epoflex MMA must be designed with consideration for:

- Future maintenance in the event of damage

- Interface details at drainage outlets, balustrade fixings, and thresholds

- Avoiding conflicting penetrations like service ducts or planter upstands

Without client involvement at design stage, the finished product may be difficult to inspect or maintain, undermining long-term safety.

The Client's Legacy: Safety Through the Building Lifecycle

Both CDM and the BSA underscore that safety doesn't stop when construction ends. The building must be safe to use, maintain, and eventually alter or demolish. That means clients need to:

- Ensure health and safety files include full as-built waterproofing drawings, maintenance guides, and membrane warranties

- Keep access and maintenance strategies practical and clearly defined

- Nominate competent individuals to manage compliance and document retention

At Premcrete, we support clients by offering structured CPD training, Gateway 2 submission support, detailed design workshops, and site inspections. We provide collateral warranties, product data, EPDs, and full digital documentation via Premtrac—all of which align with the latest expectations from both CDM and BSA.

Conclusion: Compliance is a Culture, Not a Checklist

CDM 2015 and the Building Safety Act 2022 require more than just paperwork; they require leadership. Clients must embrace their role, not avoid it. When clients lead with clarity and engage competent specialists early—especially in high-risk areas like structural waterproofing and gas protection—the outcome is a safer, better-performing building with fewer surprises down the line.

With over a decade of experience, a specialist team of CSSW-qualified professionals, and digital tools designed to meet today’s compliance standards, Premcrete is proud to help our clients meet their legal duties and deliver buildings that stand the test of time.

Let’s make safety a design priority, not a postscript.

-1.jpg)