According to BS8102:2009 there are three types of Protection. Type C protection is known as drained protection and is most commonly formed using a Cavity Drain Membrane. Table 1 of BS8102:2009 tells us that Cavity Drain systems are suitable for use in any underground structure regardless of the level of risk i.e. the height of the water table in relation to the basement slab.

A Cavity Drain system comprises a cuspated membrane applied to the walls and floor with a channel at the wall/floor junction. The membrane allows any water ingress to filter down the slab and find its way to the perimeter channel. The channel directs the water to a sump pump which is situated below the slab. The sump pump chamber will remove the water ingress to the ground-level drains.

Type C

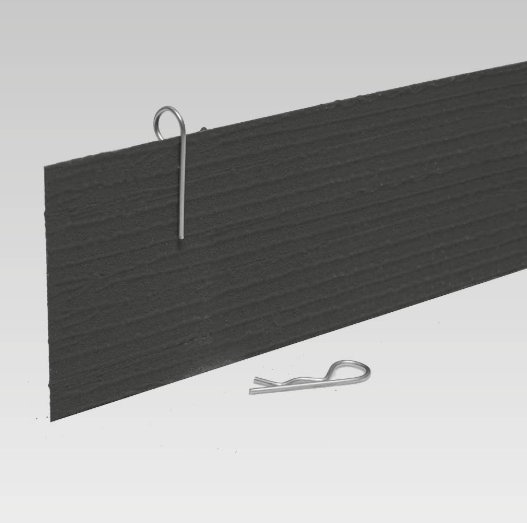

The wall membrane is typically an 8mm stud, meaning an 8mm cavity is formed, and the floor membrane typically uses a 20mm stud. The reason for this difference is that there is potential for a higher volume of water to collect on the horizontal plane than the vertical and so it is good practice to create a larger cavity to accommodate higher volumes.

Often a CSSW designer will use a Type C Cavity Drain system as part of a combined Waterproofing protection strategy. Using integrated protection, Ie: combining Type C membranes with Type B protection or Type A protection will produce a Grade Three environment. The use of combined protection is recommended by BS8102:2009 and is a requirement of NHBC and Premier Guarantee for Grade Three environments.

The cavity drain systems are great for the internal waterproofing of existing basements. If an existing basement space is being converted into new accommodation, it may not be possible to install or replace a protective barrier on the outside of the structure and so the Type C cavity drain system is an obvious choice to ensure the environment is completely dry.

“Cavity drain systems are great for internal waterproofing of existing basements.”

Things to Consider

Many considerations go into correctly designing a Type C cavity drain waterproofing system. It is recommended that a Chartered Surveyor of Structural Waterproofing is enlisted to provide professional advice on the design of the system and how to overcome specific project-related obstacles.

The floor membrane has a compressive strength of 150kN/M2 and can receive a screed directly on top of it and to provide finished floor levels and conceal the waterproofing membrane. Often the vertical wall membrane is concealed using a block or stud work wall built up in front of it to conceal the waterproofing. It is essential that the system is maintained at least every six months. Openings must be left in the concealing wall to ensure it is possible to access the flushing points and maintain the channel. When the engineer attends to maintain the channel, they should also check the sump pump to ensure everything is working in order. The sump should contain at least two pumps, one is raised slightly and acts as a backup pump.

In Conclusion

The cavity drain membranes are versatile and flexible and easy to install on brickwork, blockwork or concrete walls however great care and skill are required to ensure the cavity drain system is installed as a sealed system to provide moisture, dampness and smells do not penetrate into the basement.

City Office Real Estate recently completed LSQ London, a project to redevelop an existing building at 48 Leicester Square. The original ground floor slab was removed, and a two-storey basement was created. Premcrete helped Brookfield Europe and Make architects by designing a complete structural waterproofing system. Part of the waterproofing strategy was to use the Premcrete Hydroflow HP cavity drain membrane system.

-1.jpg)