In the construction industry, particularly within deep basement waterproofing, the pile cap interface is a crucial detail that can significantly impact the durability and safety of a structure. Traditional methods of wrapping pile caps with membranes have long been the norm. However, advancements in technology have introduced more efficient and reliable methods.

This blog is set to explore how Premcrete’s innovative waterproofing solutions can simplify your pile cap interface, eliminating the need to wrap pile caps in both waterproofing and gas protection scenarios.

Understanding the Pile Cap Interface

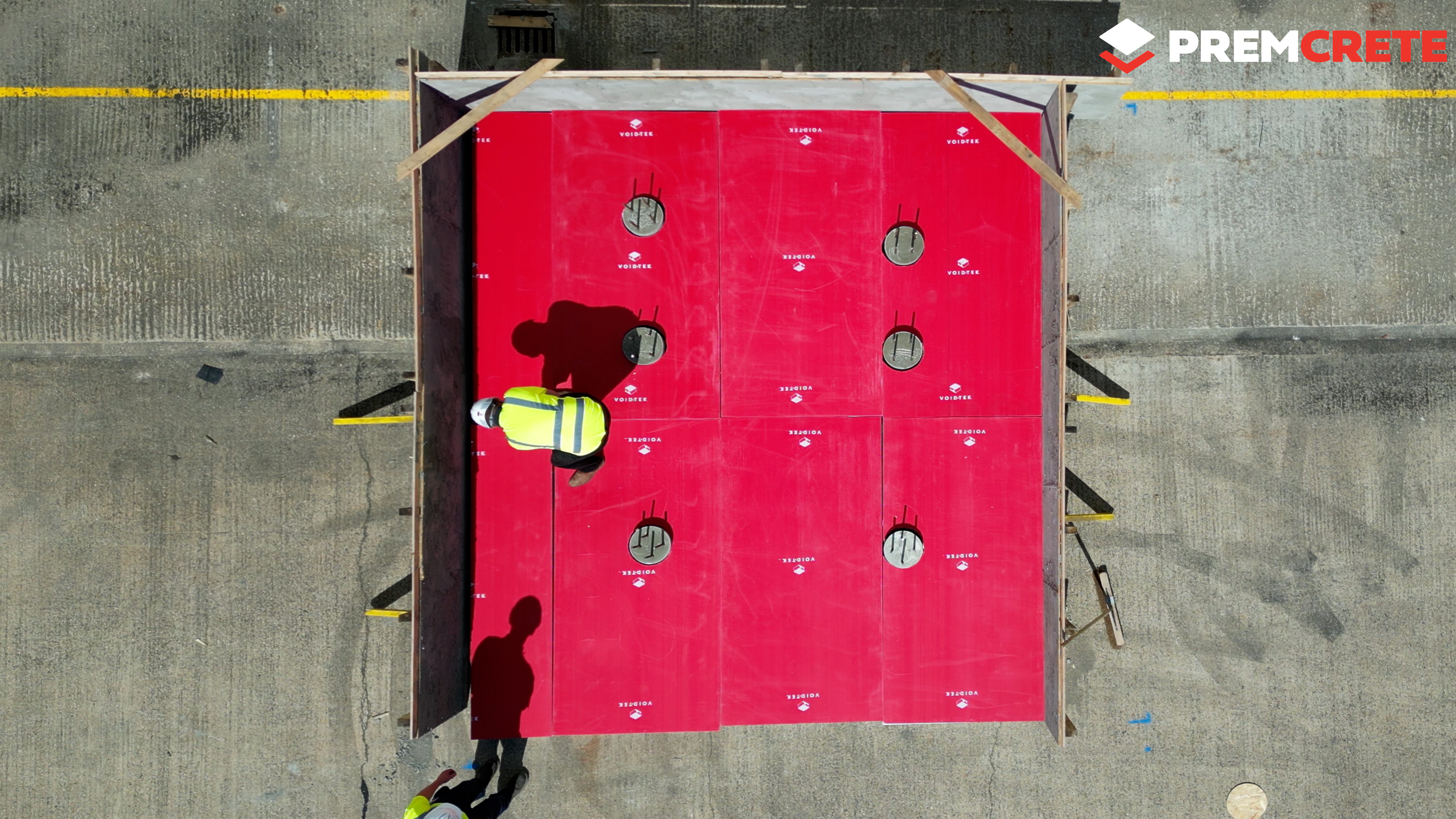

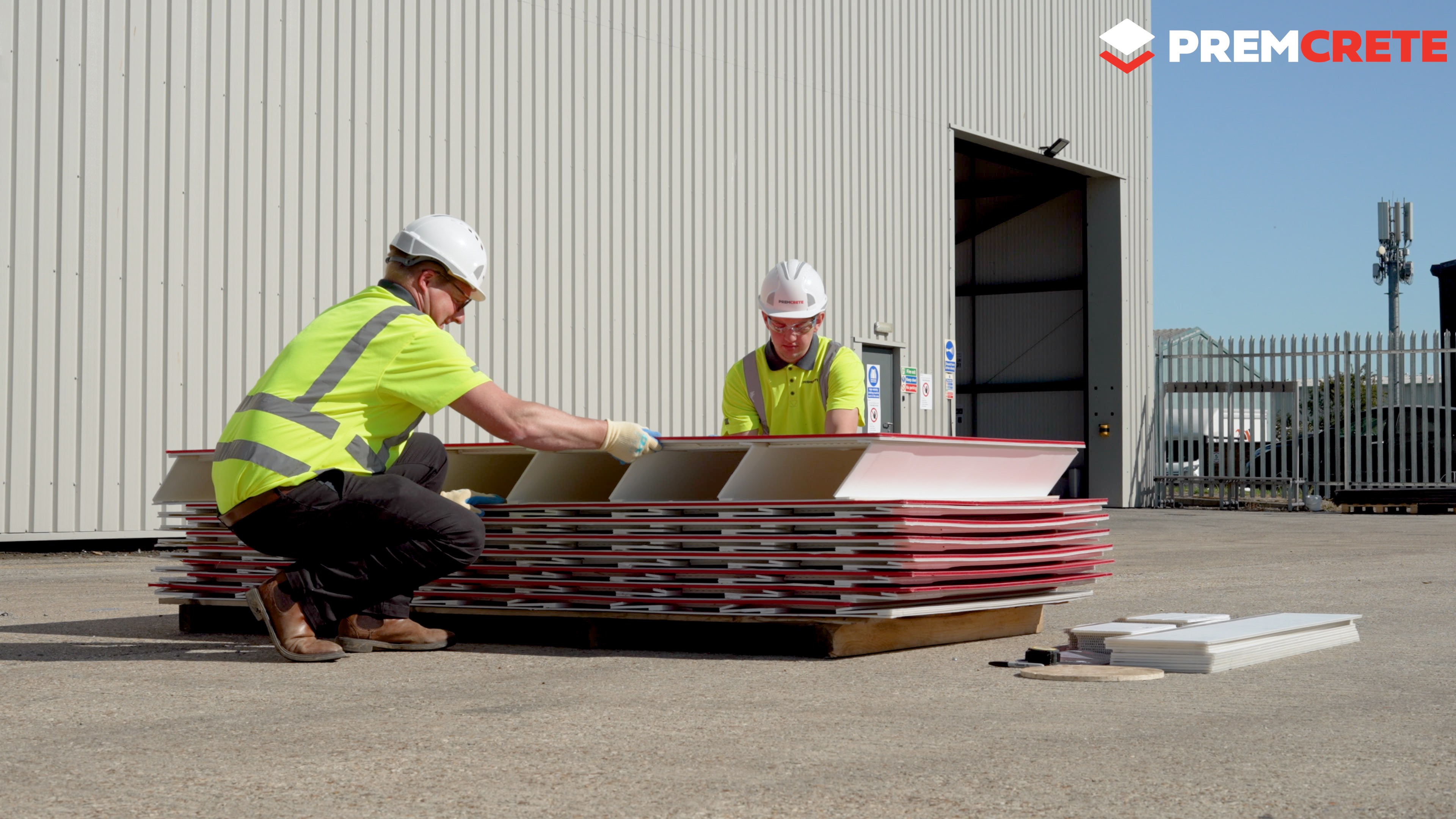

The pile cap interface is a critical point in construction where the pile cap meets the basement slab. Historically, this junction required meticulous wrapping of the pile caps with membranes to ensure waterproofing integrity. While effective, this method is labour-intensive and time consuming. At Premcrete, we have pioneered new interfaces that eliminate the need for wrapping pile caps, offering a streamlined and efficient solution.

In a waterproofing scenario…

Our Maxiprufe pre-applied waterproof membrane is designed to be installed underneath the basement slab. This system seamlessly connects with the pile cap, where Hydroseal FX, a high performance coating, is applied to the top of the pile cap. This approach not only saves time, but also ensures a robust seal.

A quick recap…

Maxiprufe: Is a pre-applied waterproof membrane installed beneath basement slabs.

Hydroseal FX: Is a coating applied to the top of pile caps, enhancing the waterproofing system.

Transitioning Between Membranes

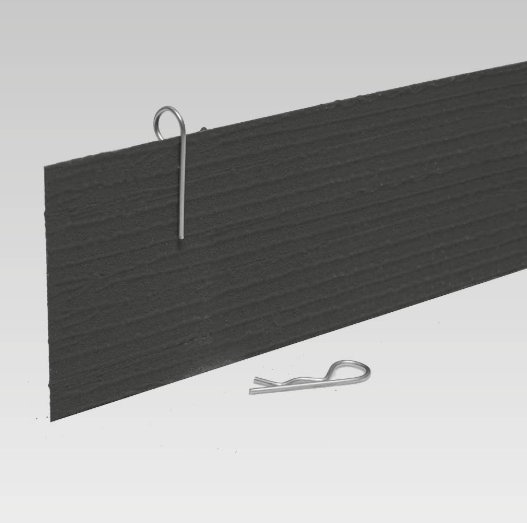

One of the challenges in waterproofing is ensuring seamless transitions between different membranes. At the perimeter of the pile cap, we use a bitumen primer to aid the adhesion of HCR butyl tape connecting it with Maxiprufe Plus. This method is fully detailed in our product key, providing you with the confidence and knowledge of proper installation sequences.

A quick recap…

Bitumen primer: Enhances adhesion for a secure membrane connection.

HCR Butyl Tape: Ensures a tight seal between different waterproofing membranes.

Addressing Gas Risks with Combi-Seal

In projects where gas risk is a concern, Combi-Seal membrane offers an effective solution. Traditionally, this membrane wraps around the full perimeter of the pile cap, with a perimeter sealing compound. While effective, this method can be cumbersome. Our innovative approach allows for overcoating the top of the pile cap with Hydroprufe LG, simplifying the process and maintaining high performance.

The Benefits of Our Approach:

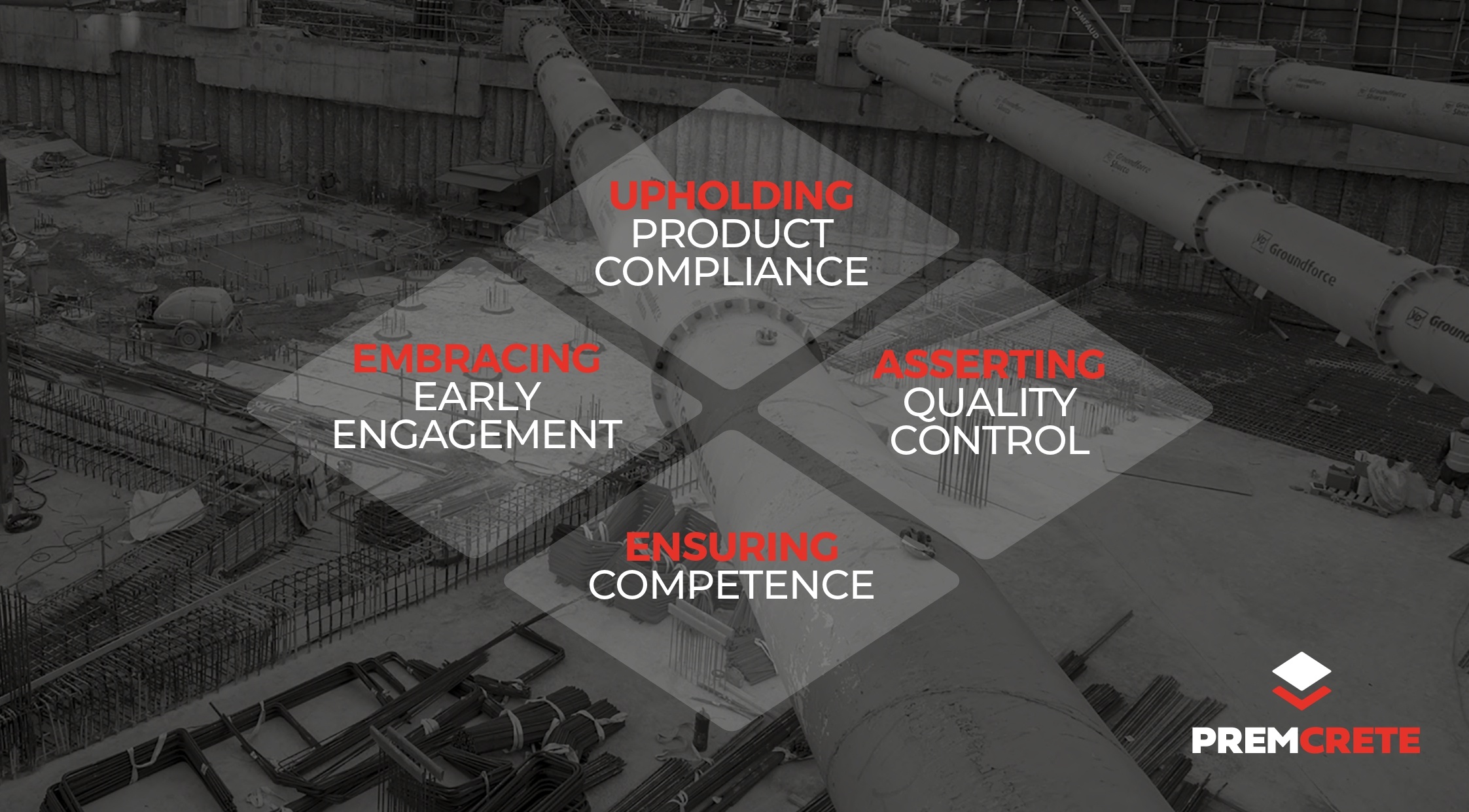

Our methods for pile cap interfaces offer several advantages:

Efficiency: Reduces installation time and labour cost.

Reliability: Ensures robust protection against water, gas and VOCs; without wrapping the pile cap.

Reduces waste: Material wastage is reduced and easier to predict, compared to traditional methods.

Check out an example of a typical section through pile cap PDF below, with product layers to make it simple to use and visualise:

You can find more of these on our Learn to Design Waterproofing page by clicking here.

Don’t forget. These are completely FREE to download!

In Conclusion

At Premcrete Ltd, we are committed to redefining waterproofing solutions. Our advanced methods for pile cap interfaces not only simplify the installation process but also ensure the highest standards of protection for your substructure. Whether you are dealing with water, gas or ground heave, our products offer the reliability you need.

For more information on how to design waterproofing for your substructure, check out our latest Premcrete Academy Page – which is packed full of free resources to help you on your way.

Need some more support? Contact us today on: sales@premcrete.com

-1.jpg)