Have you ever wondered why some buildings seem to shift or tilt over time, despite being constructed on seemingly stable ground? The answer lies in a phenomenon known as ground heave – a subtle yet potentially devastating force that can wreak havoc on structures, particularly those built on clay soil.

Ground heave, characterized by the upward movement of the earth, is often a consequence of the expansive nature of clay soils. These soils tend to swell when moist, exerting pressure on anything built atop them. It’s a stark contrast to settlement, caused by the weight of buildings, or subsidence, where the ground sinks downwards.

Even the slightest ground displacement, often less than 150mm, can spell trouble for buildings, leading to significant structural damage to walls and foundations. Surprisingly, this upheaval isn’t always triggered by seismic events or geological shifts; it can also be induced by seemingly innocuous actions, such as the removal of mature trees.

Now, ground heave is not new – it has, of course, been an issue within the world of construction for many years. However, this article is set out to explore new ways to address the age-old problem… and provide a solution.

How is ground have dealt with currently?

Traditional methods of ground heave protection have existed for many years… yet they often come with a myriad of challenges.

In the usual cases of dealing with ground heave protection, conventional wisdom has often dictated the use of polystyrene cellular structures or void formers. Placed beneath the foundation, these structures aim to create a void, allowing for the upward movement of the ground while preserving the integrity of the structure above.

At first glance, this approach may seem like a logical solution. However, as construction professionals are discovering, the reality is far from ideal. Here’s why traditional methods involving polystyrene are increasingly falling out of favour:

- Excessive Digging: One of the primary drawbacks of traditional polystyrene void formers is their tendency to require excessive digging. Often oversized and unable to compress sufficiently, these structures demand more excavation than necessary, leading to increased labour costs and project delays.

- Bulky and Cumbersome: Transporting, handling, and storing polystyrene void formers pose significant logistical challenges. Their bulky nature not only adds to transportation costs but also complicates on-site manoeuvrability, consuming valuable space, and resources.

- Vulnerable to Damage and Waste: Polystyrene void formers are notoriously fragile, prone to damage during handling and installation. This susceptibility to breakage contributes to approximately 10% wastage on average, resulting in costly disposal expenses and environmental concerns.

- Environmental Hazards: Perhaps most concerning is the environmental impact of polystyrene. As it breaks down molecularly over time and releases harmful chemicals, it poses a threat to both ecosystems and human health. Additionally, its static nature can attract and trap pollutants, further exacerbating environmental degradation.

In summary, while traditional methods may have once seemed like the go-to solution for ground heave protection, their inherent flaws are now coming to light. As construction practices evolve and sustainability becomes paramount, it’s clear that alternatives to polystyrene void formers are not only desirable but necessary for the future of the industry.

“Ground heave is not the only upheaval on your site… polystyrene is”

What’s new in ground heave protection?

Luckily for the industry… there’s a brand-new product in the market to tackle the aforementioned issues head on.

Enter… VOID-TEK.

What is VOID-TEK?

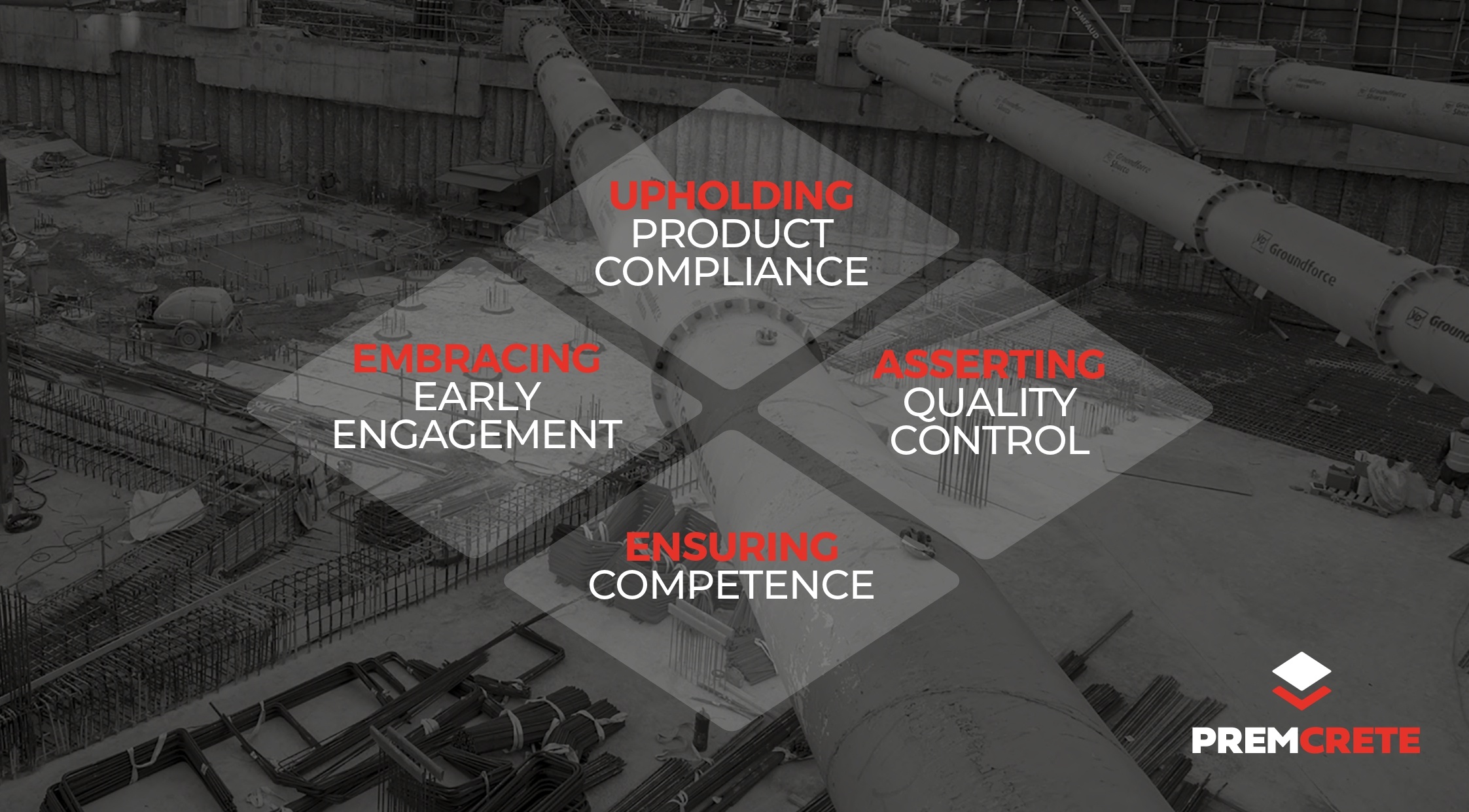

At the core of VOID-TEK lies a commitment to innovation and client-centric solutions. Developed in response to invaluable feedback from construction site stakeholders, VOID-TEK represents a significant departure from traditional ground heave protection systems.

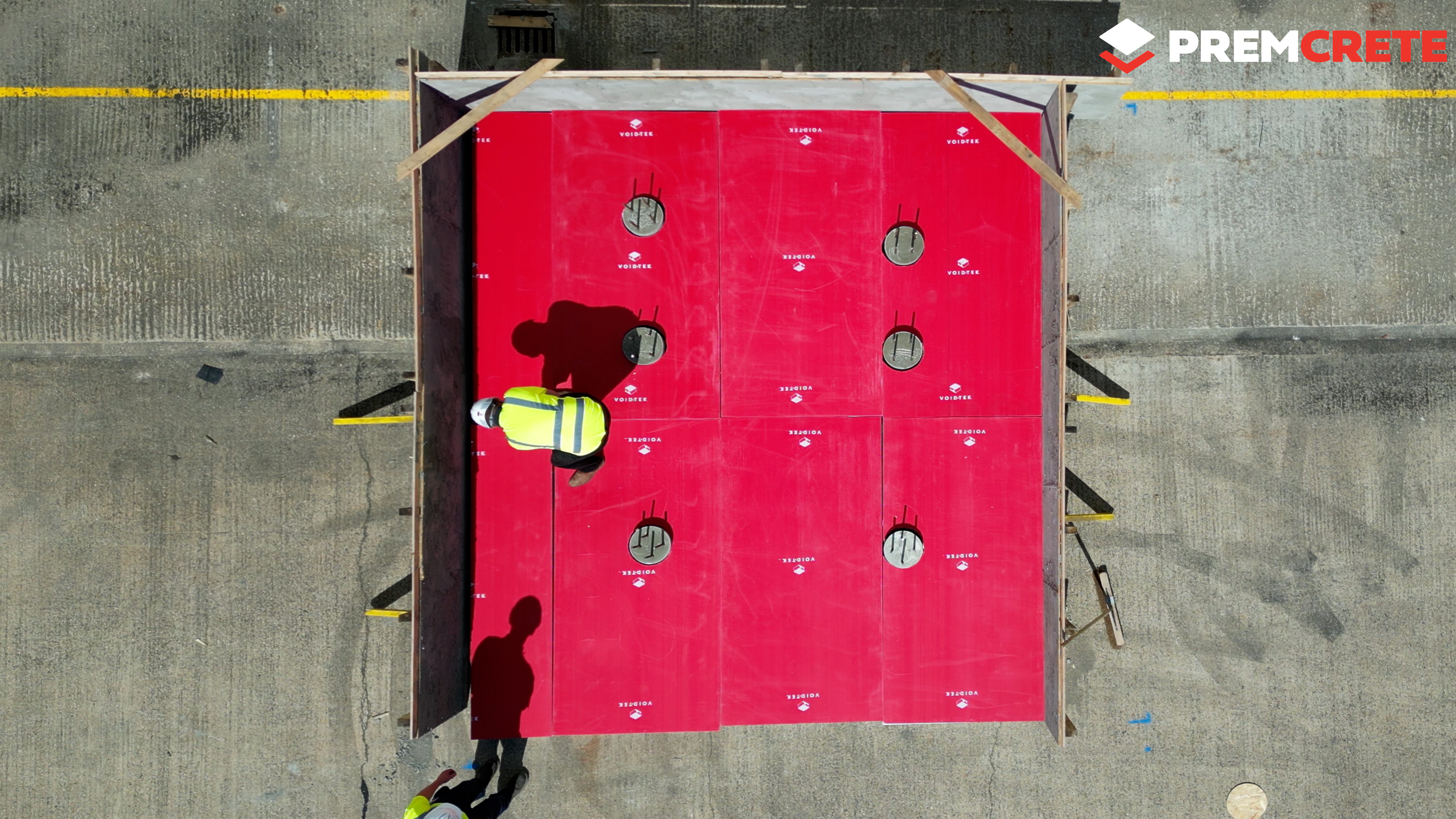

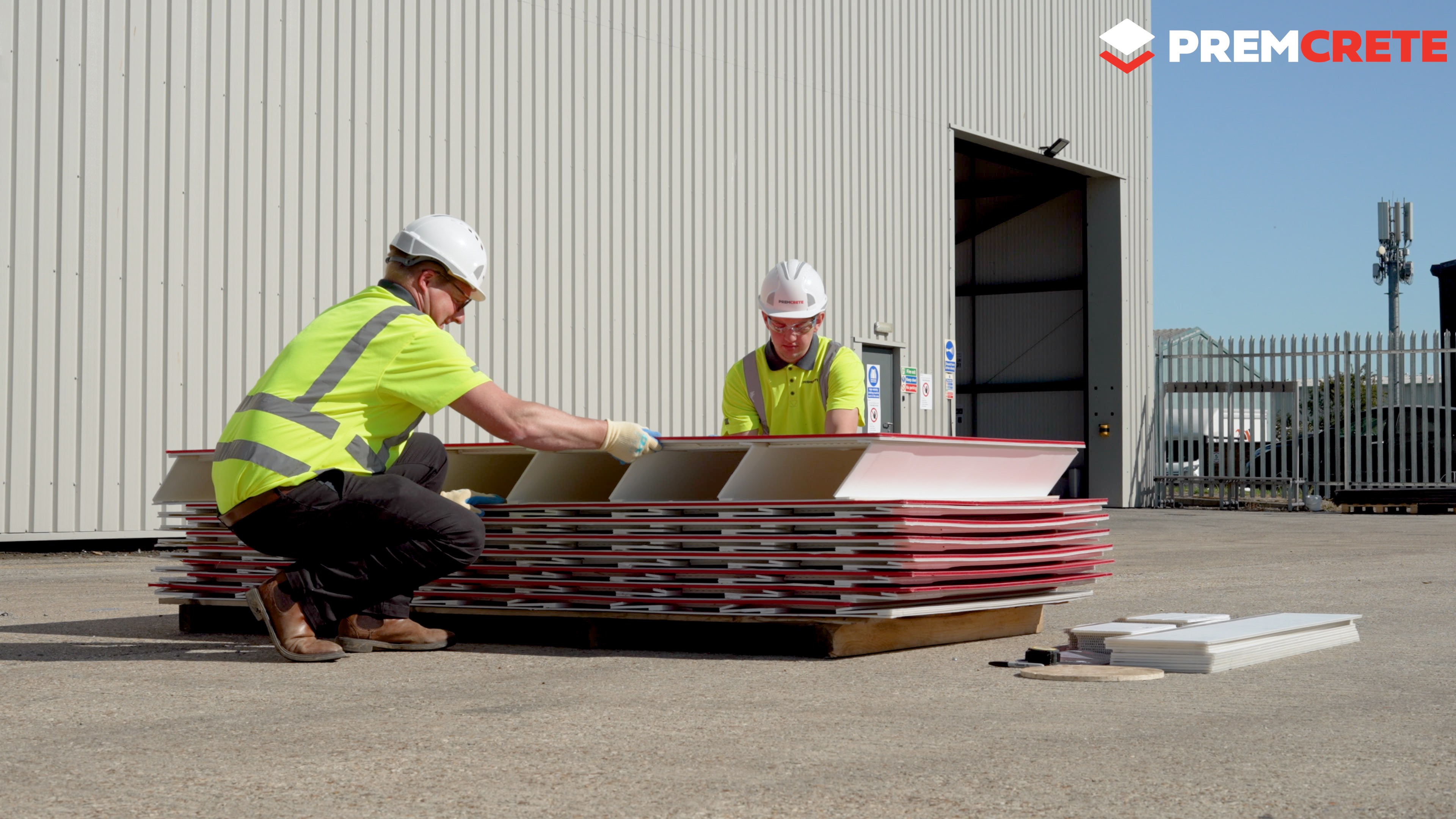

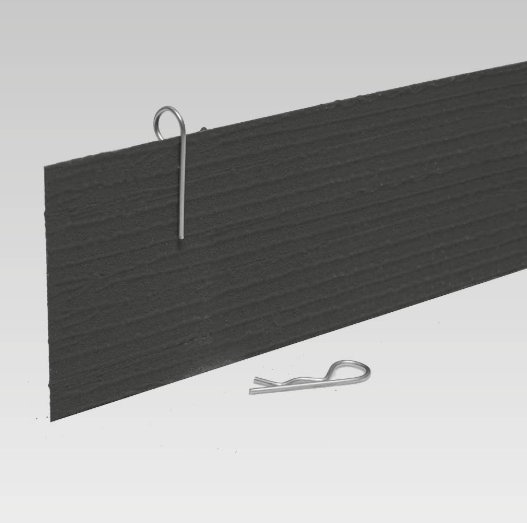

Unlike its counterparts, VOID-TEK is exclusively crafted from Polypropylene Fluted Board, offering unmatched durability and resilience. In contrast to conventional polystyrene-based systems, which are prone to damage and deterioration, VOID-TEK remains steadfast, ensuring consistent performance even in adverse conditions.

The journey to bring VOID-TEK to fruition has been one of dedication and perseverance. Over nearly half a decade, the Premcrete team has tirelessly tested and refined the technology, subjecting it to rigorous concrete pours and extensive product evaluations. This meticulous process has culminated in the acquisition of a patent, a testament to VOID-TEK’s reliability and effectiveness.

The VOID-TEK Advantage

VOID-TEK offers a comprehensive solution that addresses the shortcomings of traditional methods for the following reasons:

Labor and Cost Reduction: Streamline operations and minimize expenses by reducing the need for extensive digging and labour-intensive processes.

Efficient Transportation and Storage: Optimize logistics with flat-packed delivery, saving space, time, and resources.

Effortless Installation: Enjoy a hassle-free assembly process with minimal breakage, ensuring a smooth and efficient installation experience.

Environmental Responsibility: Embrace sustainability with VOID-TEK’s eco-friendly materials, eliminating hazardous waste and reducing environmental impact.

Robust Durability: Built to withstand the rigors of construction, VOID-TEK offers unparalleled strength and resilience, ensuring long-lasting performance.

Certified Quality and Protection: Rest assured with VOID-TEK’s rigorous testing and patented technology, providing peace of mind and reliability.

Case Study: Realizing Real Savings with VOID-TEK

Project Overview

Imagine the potential savings and efficiencies gained by choosing VOID-TEK as your preferred ground heave solution. Let’s examine a hypothetical case study based on a project in London with the following specifications:

- Ground Area: 1420 sqm

- Soil Type: London Clay (plasticity 40-60%)

- NHBC Void Requirement: 150mm

Calculating the Savings

Dig Depth, Deliveries, Unloading Time, Storage Area, Speed of Install, Waste Allowance, Skip Hire

Here’s a breakdown of the estimated savings based on various factors:

- Reduced Labour and Plant Hire Costs: With VOID-TEK’s innovative design, there’s a predicted reduction in labour and plant hire costs.

- Transportation Efficiency: The delivered and stored size of VOID-TEK allows for significant reductions in the number of delivery vehicles required, leading to savings in fuel, emissions, and on-site management.

- Faster Unloading Time: VOID-TEK’s efficient design drastically reduces unloading time compared to conventional products, resulting in substantial labour and time savings.

- Faster Installation: VOID-TEK offers a 25% faster installation time, reducing overall project timelines and costs.

- Less Wastage: With VOID-TEK, there’s a significant reduction in waste compared to conventional products, leading to savings in disposal costs and skip hire.

- Optimized Storage: VOID-TEK requires less storage area and is easier to handle, reducing logistical complexities and costs associated with storage.

In Conclusion

In this case study, we’ve seen how choosing VOID-TEK as the ground heave solution for a construction project can lead to substantial cost savings and operational efficiencies across various aspects of the project lifecycle. From reduced labour and transportation costs to faster installation and minimal wastage, VOID-TEK offers a comprehensive solution that not only addresses the challenges posed by ground heave but also enhances overall project outcomes.

By embracing innovative technologies like VOID-TEK, construction professionals can streamline operations, minimize environmental impact, and ultimately deliver projects more effectively and sustainably.

Disclaimer: The figures and calculations provided in this case study are based on industry knowledge and estimations. Actual savings may vary depending on project-specific factors. Readers are advised to conduct their own assessments and consult with relevant experts for accurate cost evaluations.

Conclusion: Your Trusted Partner in Construction

With VOID-TEK, you’re not just investing in a ground heave solution; you’re investing in a trusted partner committed to enhancing your project outcomes. Experience the VOID-TEK advantage today and revolutionize your construction endeavours.

Click here to find out all you need to know about VOID-TEK – including our new brochure and data sheet.

Want to see VOID-TEK in action? Click below to check out our latest VOID-TEK video… and explore the rest of our YouTube channel – containing plenty more Premcrete playlists!

Structured for Peace of Mind with Premcrete

Premcrete stands as your reliable ally in the realm of construction. With a blend of extensive experience, technical expertise, and a diverse product range, we are dedicated to delivering solutions tailored to your specific needs. From below-ground structural waterproofing to gas protection, our offerings include epoxy and cementitious screeds, resin flooring systems, technical grouts, anchor resins, joint sealants, and high-quality concrete repair systems.

At Premcrete, we not only provide solutions but also offer designs for substructure protection against water and gas ingress, ensuring compatibility with all related ancillary products within our range. Trust Premcrete to structure your projects for peace of mind and unparalleled success.

-1.jpg)