At Premcrete, we understand the complexities involved in basement construction and waterproofing. This blog post aims to guide architects, structural engineers, and contractors through the detailed process of configuring piled basement walls, ensuring optimal protection against water, gas, and ground heave.

Why Detailing Matters

Detailing a piled basement wall involves more than just placing materials; it’s about creating a cohesive system that addresses all potential vulnerabilities. Proper detailing can prevent future issues, save costs on repairs, and ensure the longevity of the structure.

Waterproofing:

For a Grade 1A or 1B basement, a single form of waterproofing might be sufficient. In this case, we recommend using Hydrocrete watertight concrete in conjunction with Cemflex VB and Hydrostop BR water bars at construction joints.

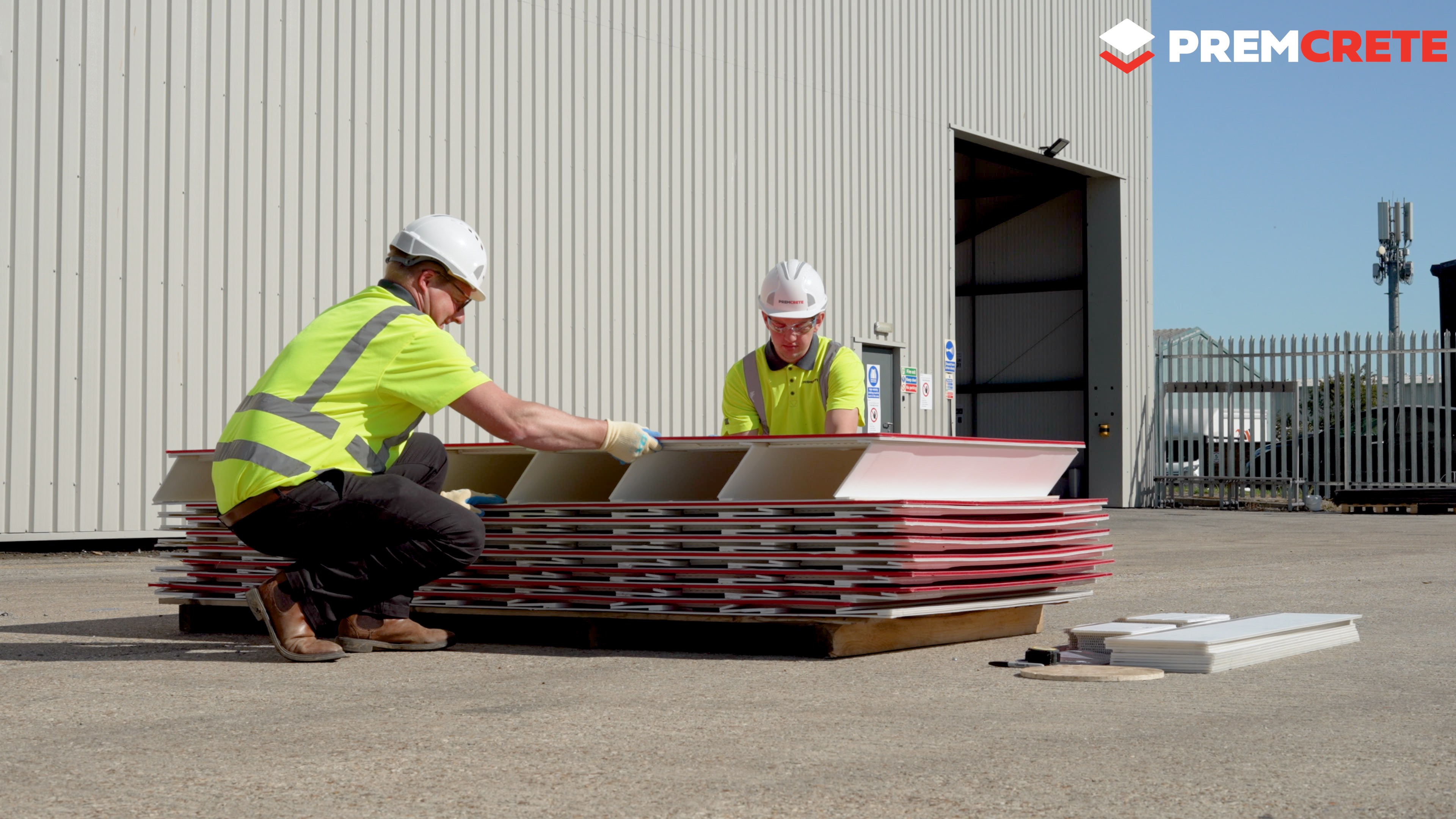

For higher-grade basements (Grade 2 or 3) dual protection systems are necessary. This typically involves a pre-applied membrane like Maxiprufe Plus.

Gas Protection:

In areas where gas protection is required, a standard waterproof membrane won’t suffice. The Combi-Seal membrane, which offers combined gas and waterproof protection, is ideal for such scenarios.

Interface Detailing:

One of the critical challenges in detailing is managing the interfaces, particularly between secant or contiguous piles and the capping beam. The use of cementitious coatings and Twinseal compounds ensures a secure seal around the pile heads and effective connection of membranes to the capping beam.

“Detailing a piled basement wall involves more than just placing materials; it’s about creating a cohesive system”

1. Assessing the Basement Grade

Start by determining the grade of your basement according to BS 8102:2022. This will dictate the level of protection required.

2. Selecting Waterproofing Systems

For Grade 1 basements:

Use Hydrocrete watertight concrete

Integrate Cemflex VB and Hydrostop BR water bars

For Grade 2 or 3 basements:

Apply Maxiprufe Plus as a pre-applied membrane

Ensure the correct positioning of the membrane to cover all critical areas

3. Managing Interfaces

At the interface between the pile head and the capping beam:

Apply a cementitious coating.

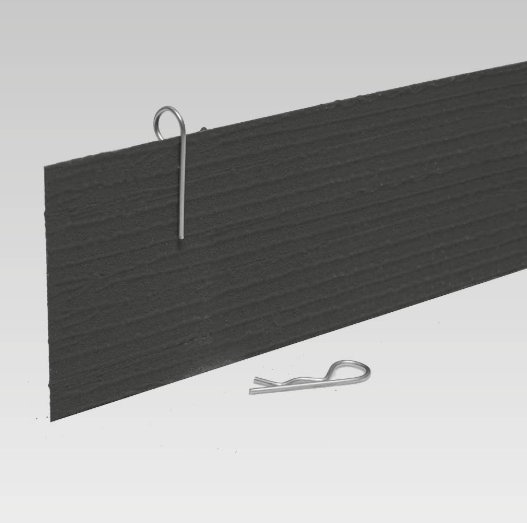

Use Twinseal compounds to seal around the pile and connect to the membrane.

4. Incorporating Gas Protection

In gas-prone areas:

Replace the Maxiprufe Plus with the Combi-Seal membrane.

Adjust the detailing to ensure both gas and waterproof protection are maintained.

Visual Guide and Resources

For a more comprehensive understanding, refer to our detailed video tutorial available on the Premcrete Academy website.

In Conclusion

At Premcrete Ltd, we are committed to providing advanced waterproofing solutions that address the critical needs of your substructure.

Discover a multitude of completely FREE resources to help you learn to design your own waterproofing project here.

-1.jpg)